- Joined

- Jan 20, 2016

- Messages

- 602

Its upgrade time! I've got some new parts coming for the mill so I figured I would post a quick update, as well as summarize the costs for everything so far in case anyone else is looking to go the same route.

Parts and costs all including shipping:

2 400 oz in Nema 23 steppers - $67

1 1000 oz in Nema 34 stepper - $69.79

2 DM542T stepper drivers - $67.90

1 DM860T stepper driver - $53.95

1 550 mm SFU1605 ballscrew - $65

1 750mm DFU1605 ballscrew - $50

1 350mm DFU1605 ballscrew - $50

6 7001 AC bearings - $15.54

3 flexible couplers - $15

4 inch mill vise - $100

PM-25 mill - $1649

350 watt power supply - $30

240 watt power supply - $20

Break out board - $10

Aluminum stock - $10

Total - $2271.18

I am hoping to install the new drivers today. I am hoping they run much smoother than the TB6600s. I think the ballscrews are supposed to be delivered tomorrow, so I will update once I figure out if they are any good.

For the tool changer, I have a piece of 4 inch aluminum bar 8" long being delivered tomorrow to make an air cylinder. I also have 36" of 12L14 steel for tool holders coming. The mill will probably be used in lathe mode to make most of those. I also made the umbrella a little bit bigger to hold 12 tools instead of 10.

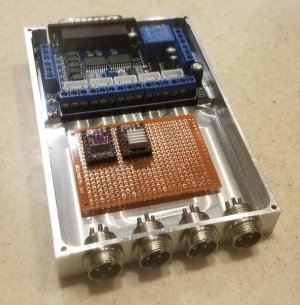

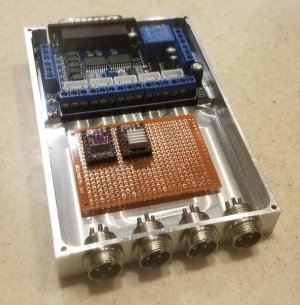

I also finished the first part CNCd part made on the machine. I got the backlash figured out and I got the X axis to stop losing steps. It is the electronics box for my micro lathe. This machine really can rip up some metal.

Parts and costs all including shipping:

2 400 oz in Nema 23 steppers - $67

1 1000 oz in Nema 34 stepper - $69.79

2 DM542T stepper drivers - $67.90

1 DM860T stepper driver - $53.95

1 550 mm SFU1605 ballscrew - $65

1 750mm DFU1605 ballscrew - $50

1 350mm DFU1605 ballscrew - $50

6 7001 AC bearings - $15.54

3 flexible couplers - $15

4 inch mill vise - $100

PM-25 mill - $1649

350 watt power supply - $30

240 watt power supply - $20

Break out board - $10

Aluminum stock - $10

Total - $2271.18

I am hoping to install the new drivers today. I am hoping they run much smoother than the TB6600s. I think the ballscrews are supposed to be delivered tomorrow, so I will update once I figure out if they are any good.

For the tool changer, I have a piece of 4 inch aluminum bar 8" long being delivered tomorrow to make an air cylinder. I also have 36" of 12L14 steel for tool holders coming. The mill will probably be used in lathe mode to make most of those. I also made the umbrella a little bit bigger to hold 12 tools instead of 10.

I also finished the first part CNCd part made on the machine. I got the backlash figured out and I got the X axis to stop losing steps. It is the electronics box for my micro lathe. This machine really can rip up some metal.