- Joined

- Sep 7, 2022

- Messages

- 4

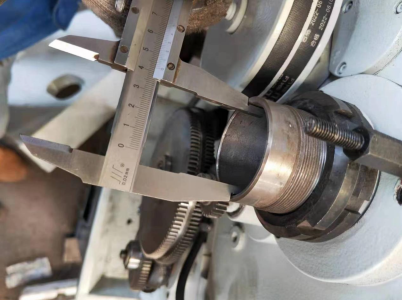

Hi there, this is my first time using this forum and I have a lot to learn still about it. Quick question I'm hoping you folks could answer if you know. When ordering a lathe with a 51mm through spindle bore that does that mean that you can slide a 50mm round stock through the spindle all the way through the spindle. Or does that cited dimension not take into account the parts resulting in an actual smaller diameter workpiece fit?Having been in the same position years ago, I ended up with the 1340GT because I previously had a Chinese mainland mill and regretted all the fit and finish issues. If you have the fund's buy the best you can. Also, do not count what comes with the lathe, chances are the more you get the cheaper it is. Buy better, buy less. The 4J Chinese chuck that came with my previous lathe was junk.