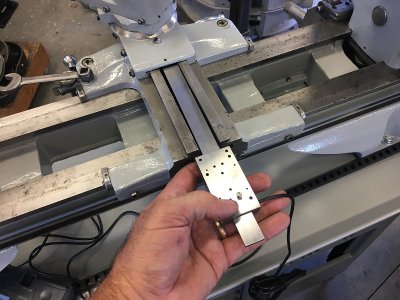

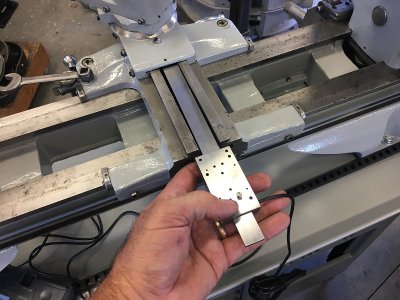

Back on the project. I bought a 32” and 6” iGaging absolute DRO. They are compact, looked like they’d package up nicely, and I figured good enough for what’s it’s for. I searched and found a couple good threads by forum members who had used them on mounting the cross-feed scale and decided to mount it in this position.

I don’t like how far it extends out the back of the saddle with this approach but it’s well protected, doesn’t encroach on tailstock positioning, nor risk getting whacked on the headstock side. Plus, there are a couple threaded holes on the backside of the carriage begging to be used to mount things. I figured I could mount both axis with one bracket but needed a piece of stock 4” wide by 1.25” thick, which I didn’t have, so a made a quicky lost foam pattern on the router table and cast a couple aluminum machining blanks for the scale mounts…..it’s nice to be able to put metal where you want it….

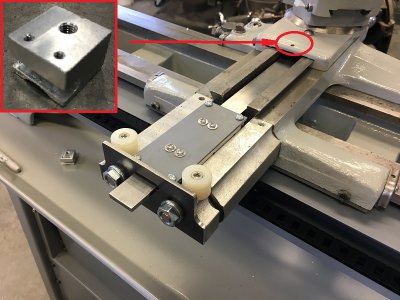

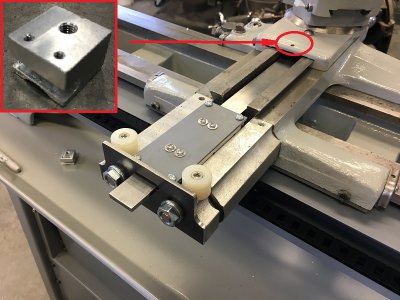

I wouldn’t have gone to the trouble but I get a lot of mileage out of this part. There’s are a lot drilling and tapping and little bits and pieces I made to mount the cross feed scale, but it works well and can come off quickly if ever needed.

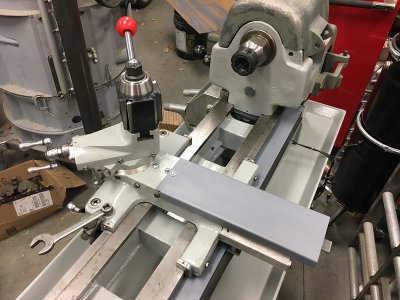

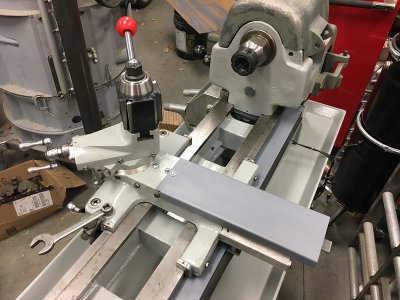

I made an 18-gage sheet metal chip guard to cover it all up. I bought an AXA wedge QCTP. It came with 8 tool holders. Chinesium for sure, but seems pretty decent. Not much more to say other than machined the nut-blank to fit the lathe’s tool post holder.

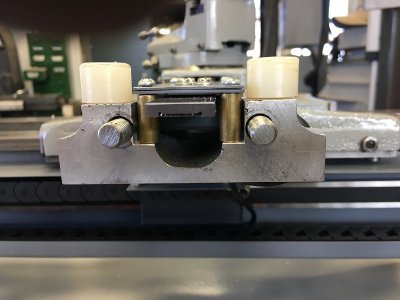

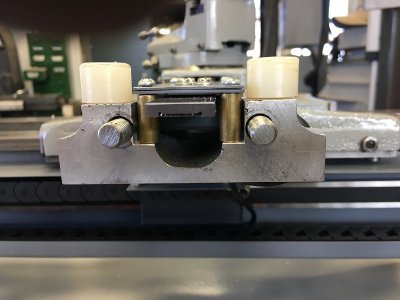

I debated enclosing the scale on the bed but ultimately decided to do so. The sensor on the bed scale mounts to the casting via a sheet metal bracket and travels with the saddle. I bought some chain drag cable carrier and here’s how everything mounts up.

The cover for the guard has a piece of rubber sheet that deflects as the scale travels through it but otherwise keeps things sealed up.

Making the hardware for mounting the DROs certainly took some time but I think it was worth the effort. I sketched up a bracket for the DRO display that mounts to the cabinet, but I may mount it to the wall. I’m going to wait to fab that up until I get the cast guards worked out and mounted.

I need to get the motor mounted and get the machine under power. -Still more to do.

Best,

Kelly