-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

NEW ACRA 1640TE

- Thread starter Firestopper

- Start date

- Joined

- Mar 12, 2014

- Messages

- 1,531

Hey looky there Paco, CHIPS!!!

Looks great my friend.

Mike

Looks great my friend.

Mike

- Joined

- Nov 7, 2018

- Messages

- 186

Thanks Nez,Impressive machine you got there, Paco.

Nez

To say I'm very pleased with it, would be understated.

Paco

- Joined

- Nov 7, 2018

- Messages

- 186

Hey looky there Paco, CHIPS!!!

Looks great my friend.

Mike

Yea, finally made some.

Every machine has their own idiosyncrasy/personality. I could control the 1440 with ease after 17years. I got some learning to do.

Thanks Mike!

Paco

- Joined

- Nov 24, 2014

- Messages

- 3,572

Thanks for posting the process Paco. She's a beauty.

Nothing left to do now but make parts.

Just wondering, did the machine come with a jog function or is that something Mark added via the VFD?

Like you indicated, that joy stick will be a joy to use in a number of scenarios. I would like to try it for indicating parts in a 4 jaw. No need to shift to neutral and drag the chuck around when the RPMs are that low and controllable.

I know you won't mind the reminder, keep safe.

When do we get the next installment on the brake?

Nothing left to do now but make parts.

Just wondering, did the machine come with a jog function or is that something Mark added via the VFD?

Like you indicated, that joy stick will be a joy to use in a number of scenarios. I would like to try it for indicating parts in a 4 jaw. No need to shift to neutral and drag the chuck around when the RPMs are that low and controllable.

I know you won't mind the reminder, keep safe.

When do we get the next installment on the brake?

- Joined

- Dec 25, 2017

- Messages

- 2

How much did that 1640 cost you? I found a 1660 on penn tool co for 10k.

More than likely what you saw was a Chinese made Acra.How much did that 1640 cost you? I found a 1660 on penn tool co for 10k.

- Joined

- Nov 7, 2018

- Messages

- 186

Thanks for posting the process Paco. She's a beauty.

Nothing left to do now but make parts.

Just wondering, did the machine come with a jog function or is that something Mark added via the VFD?

Like you indicated, that joy stick will be a joy to use in a number of scenarios. I would like to try it for indicating parts in a 4 jaw. No need to shift to neutral and drag the chuck around when the RPMs are that low and controllable.

I know you won't mind the reminder, keep safe.

When do we get the next installment on the brake?

Hi extropic,

I turned the first project yesterday. Machine ran very nicely. The jog (joy stick) was added as was all the front control switches. The entire rear control board was removed and replaced with Mark's 12 24VDC system. I think the only original switches that remain are the fwd/rvs, micro safety switch for the end cover and the foot brake. I had mark remove the chuck guard micro switch as well.

More on the finger brake comping soon!

Paco

Last edited by a moderator:

- Joined

- Nov 7, 2018

- Messages

- 186

How much did that 1640 cost you? I found a 1660 on penn tool co for 10k.

More than likely what you saw was a Chinese made Acra.

So the 1640TE ran us close to 13K base machine only. Going from 1440 to 1640 was a $900 difference.

The machine you found on Penn tool is a completely different machine. The 1640TE weighs 400# more than the 1660 found on Pends website.

Richard King stated Arca offers some machines made in ML China. The Acra TE series are the same as the RML sold by Kent tool. These machines are build in Taiwan by Sun Master. I posted a video of Sum Master on the first page. I also can confirm that Tom provides machines to other dealers, in fact they (Acra) where preparing several machine headed to Sterling machinery while I was picking up my lathe there at Rancho Cucamonga.

Cant tell you much about the ACRA FEL-1660-GCY.

Paco

- Joined

- Nov 7, 2018

- Messages

- 186

I posted this up yesterday, but this morning after several attempts to log in to HM only to have an error messages and finally after successfully logging in, I noticed everything I posted including PM's where nowhere to be found. Weird....anybody else lose posts/messages?

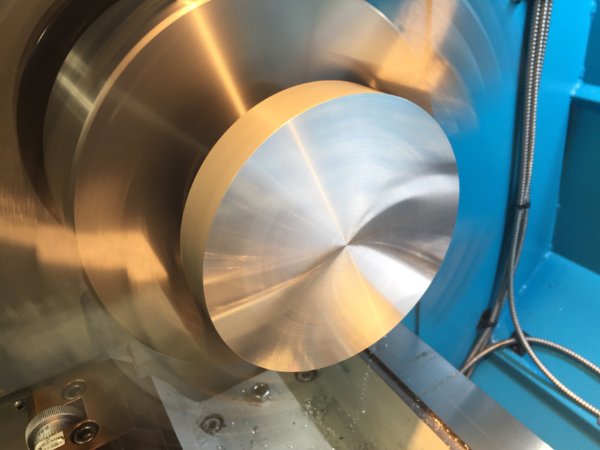

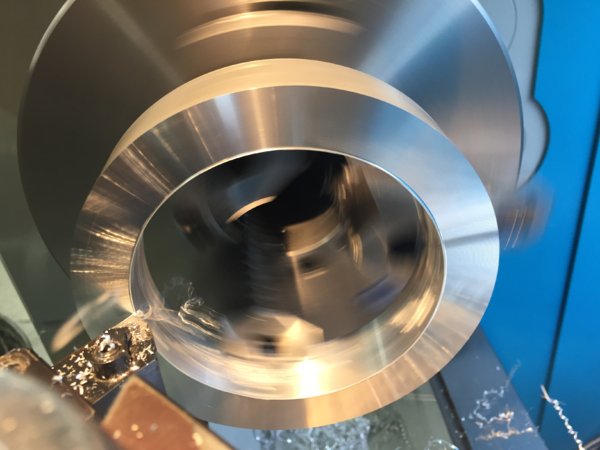

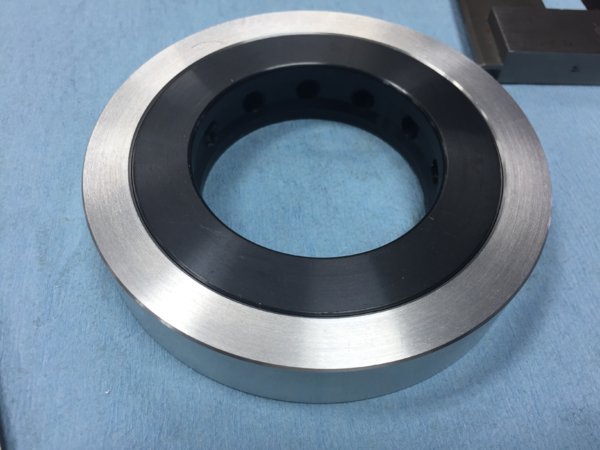

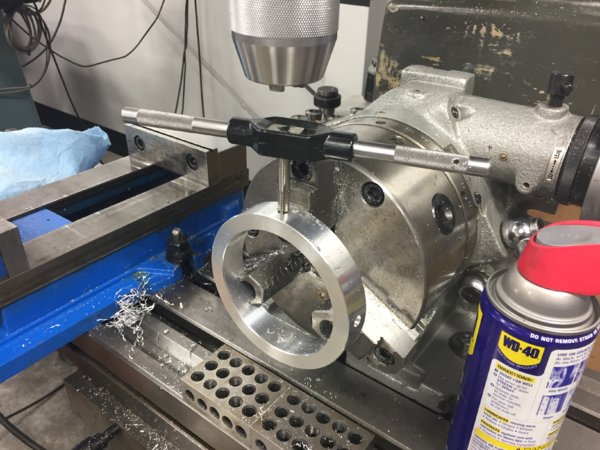

Yesterday, I turned the first project on the lathe. It's an aluminum collar that secures to the balance ring. The balance ring has 12 threaded holes evenly spaced. Only two holes (next to each other) have set screws. These holes where confusing the mag pick up sensor. I verified the ring was not magnetized so that only left the holes to blame for the unreliable RPM reading.

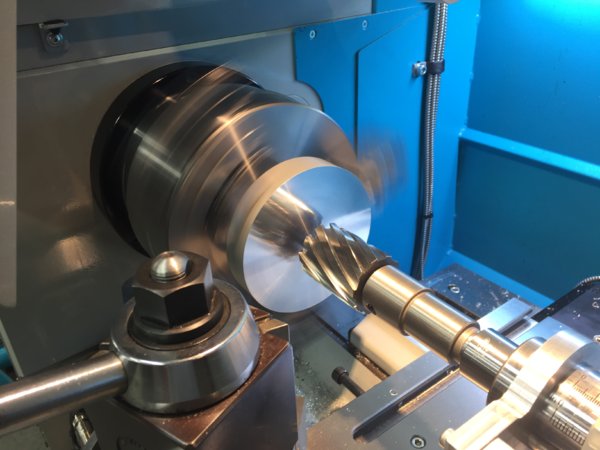

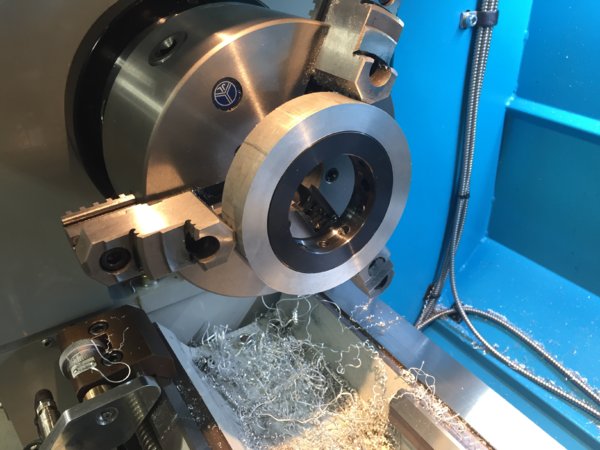

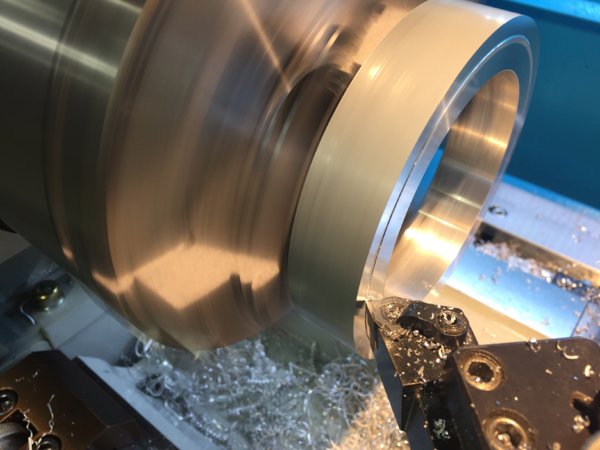

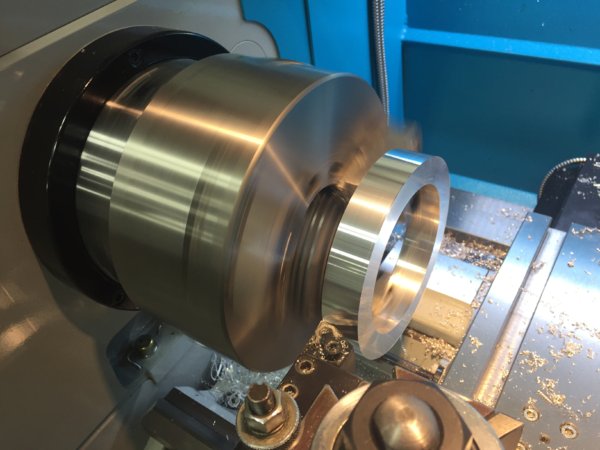

The Collar started out as 1" wide x 5" diameter disc. The piece was secured in the 3 jaw by the OD first to face, core, bore and chamfer. The piece was then rotated and rechucked by the ID. The second side was faced to final width and turned to final OD. During the boring operation, I plugged in the numbers in the DRO and took .060" per pass and one final pass twice using the reversing feed knob. The cut difference on second final pass was crazy low like .00004" The new collar first almost too tight but will slide if pulled evenly. I normally would have snuck up on the final ID/OD with the 1440, but those days are over.

The fist side faced. The surface finish was impeccable using old inserts.

Use the largest annular cutter I had to save a little time.

Bored bt the numbers including final pass.

Test fit was almost too tight.

Flipped ring and scored it by the ID. Faced to dimension and turned Diameter then Chamfered.

OD.

Almost done.

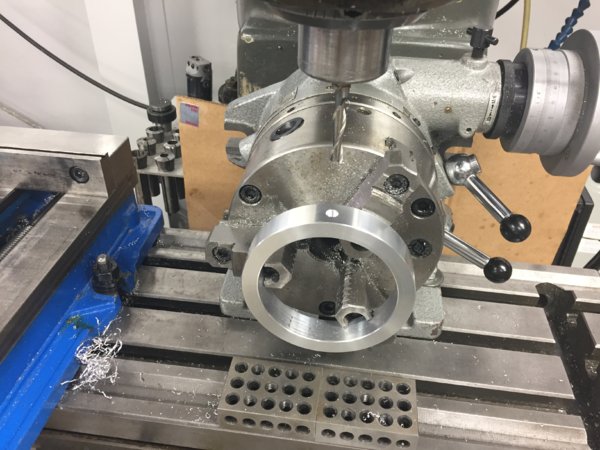

Set up the mill to create two magnet pockets 180º apart. The depth was .125" for a flush finish. Also rotated the ring 90º and drilled/tapped for a single SS set screw. The set screw will secure over the only blind hole on the ring.

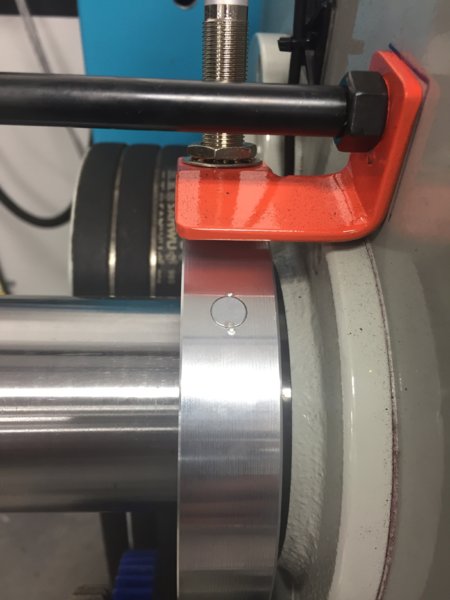

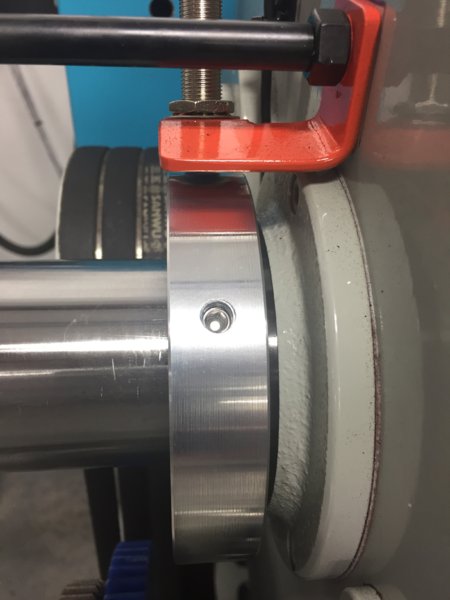

Red loc-tite was tabled into the 5/16" pockets and the magnets where set with north pole up. Two center punch strikes stake in the magnet while the red loc-tite cures. Using two magnets will provide a lower PRM reading.

The SS set screw.

The tach now works in all ranges, although the last digit still hunts +/- 2. We have a better quality sensor on order.

Here's a short video of the two stage motor brake in action. The E-stop will always brake in 1.2 seconds regardless of switch position.

Position 1 = brakes in 1.2 seconds

Position 2 = brakes in 2-5 seconds

Thanks for looking.

Paco

Yesterday, I turned the first project on the lathe. It's an aluminum collar that secures to the balance ring. The balance ring has 12 threaded holes evenly spaced. Only two holes (next to each other) have set screws. These holes where confusing the mag pick up sensor. I verified the ring was not magnetized so that only left the holes to blame for the unreliable RPM reading.

The Collar started out as 1" wide x 5" diameter disc. The piece was secured in the 3 jaw by the OD first to face, core, bore and chamfer. The piece was then rotated and rechucked by the ID. The second side was faced to final width and turned to final OD. During the boring operation, I plugged in the numbers in the DRO and took .060" per pass and one final pass twice using the reversing feed knob. The cut difference on second final pass was crazy low like .00004" The new collar first almost too tight but will slide if pulled evenly. I normally would have snuck up on the final ID/OD with the 1440, but those days are over.

The fist side faced. The surface finish was impeccable using old inserts.

Use the largest annular cutter I had to save a little time.

Bored bt the numbers including final pass.

Test fit was almost too tight.

Flipped ring and scored it by the ID. Faced to dimension and turned Diameter then Chamfered.

OD.

Almost done.

Set up the mill to create two magnet pockets 180º apart. The depth was .125" for a flush finish. Also rotated the ring 90º and drilled/tapped for a single SS set screw. The set screw will secure over the only blind hole on the ring.

Red loc-tite was tabled into the 5/16" pockets and the magnets where set with north pole up. Two center punch strikes stake in the magnet while the red loc-tite cures. Using two magnets will provide a lower PRM reading.

The SS set screw.

The tach now works in all ranges, although the last digit still hunts +/- 2. We have a better quality sensor on order.

Here's a short video of the two stage motor brake in action. The E-stop will always brake in 1.2 seconds regardless of switch position.

Position 1 = brakes in 1.2 seconds

Position 2 = brakes in 2-5 seconds

Thanks for looking.

Paco