Hey Folks, I have been setting up my 728VT as a first milling machine and have been having fun learning the basics and fabricating custom DRO brackets.

1) I initially had some issues with my y axis being incredibly hard to turn, PM support suggested adjusting leadscrew retaining plate alignment, gibbs and loosening bolts to stand (can induce twist) all helped but still getting some stiction when trying to make small adjustments. Anything else I should look into?

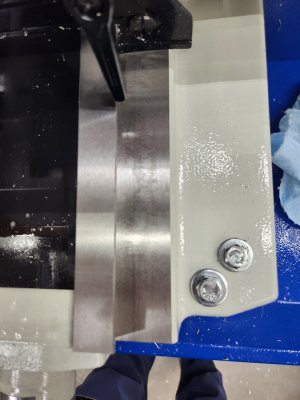

2) I noticed some coarse machining marks on the y-axis ways on the right side only (pics below). Anyone seen this before? cause for concern or potential cause of (1)?

3) My fine quill feed knob seems to have a detent in one location every complete turn. Is this normal?

1) I initially had some issues with my y axis being incredibly hard to turn, PM support suggested adjusting leadscrew retaining plate alignment, gibbs and loosening bolts to stand (can induce twist) all helped but still getting some stiction when trying to make small adjustments. Anything else I should look into?

2) I noticed some coarse machining marks on the y-axis ways on the right side only (pics below). Anyone seen this before? cause for concern or potential cause of (1)?

3) My fine quill feed knob seems to have a detent in one location every complete turn. Is this normal?