- Joined

- Dec 12, 2020

- Messages

- 33

I contacted PM and they advised that the likely culprit is that the tapered hole in the center of the chuck's backplate is undersized by 1 or 2 thousandths. They suggested using dyekem or a sharpie to color that taper in the backplate of the chuck, and then use sandpaper on a dowel to evenly remove a little from the taper to make it wider.

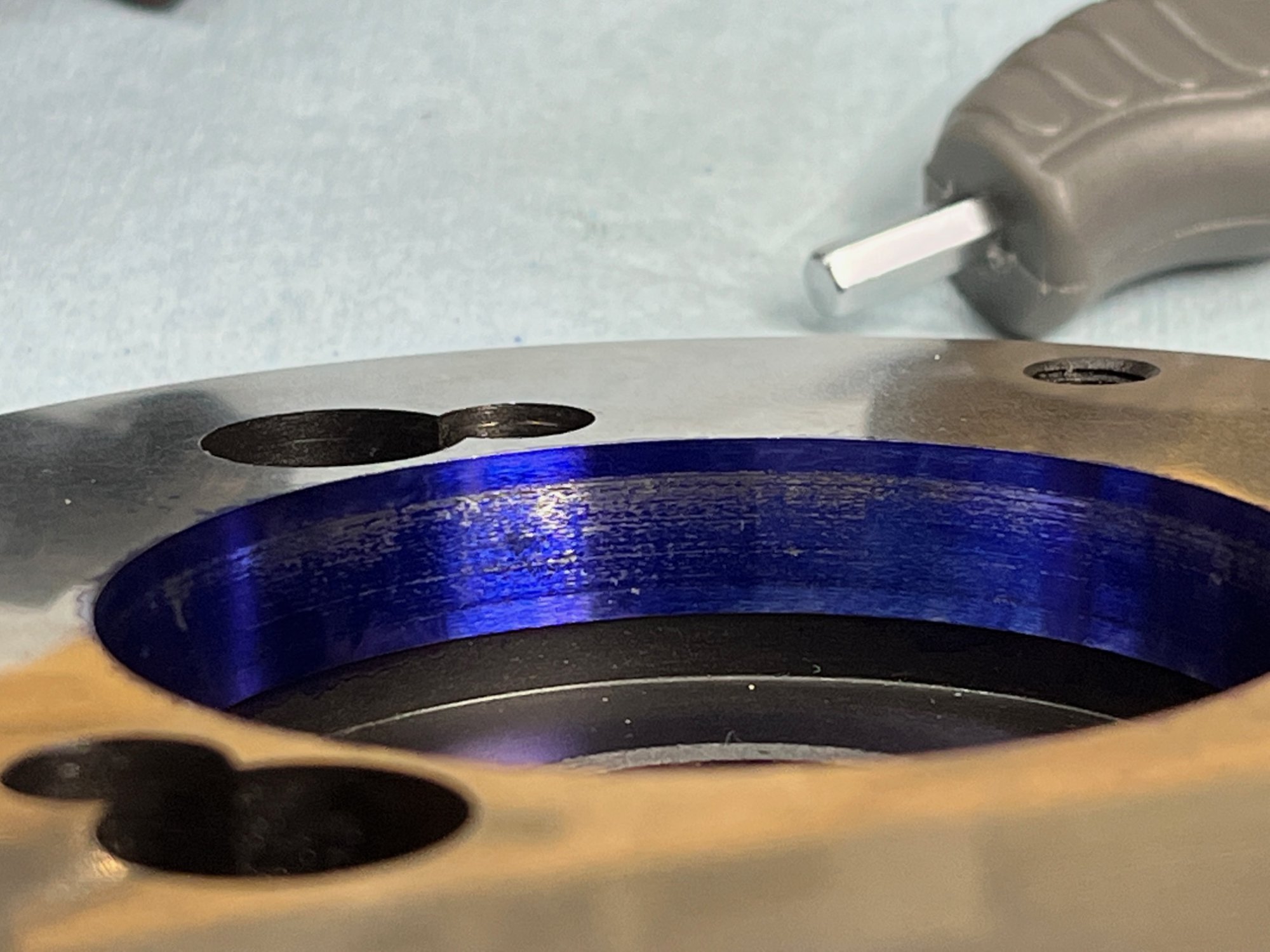

I blued up the taper and attached the back plate and removed it and found a contact ring that goes all the way around evenly. Simply adding the bluing made it much more difficult to remove the back plate. Had to hit it pretty hard with a deathblow hammer to get it off.

I took some 320 grit sandpaper on a dowel and went all the way around the interior taper. Tried it again and my runout shrank from .004-.005" to .002".

I blued it up again and got a similar pattern as this first picture, but slightly less hard/shinny contact . That's were I stopped last night. I'll repeat the process again.

What is a reasonable expectation for repeatability for this thing if it is fixed and working properly? I've been checking the runout inside the taper that the collets engage on the chuck. Assuming I mount it in the same camlock position should I be back under .0001" every time?

Thanks

I blued up the taper and attached the back plate and removed it and found a contact ring that goes all the way around evenly. Simply adding the bluing made it much more difficult to remove the back plate. Had to hit it pretty hard with a deathblow hammer to get it off.

I took some 320 grit sandpaper on a dowel and went all the way around the interior taper. Tried it again and my runout shrank from .004-.005" to .002".

I blued it up again and got a similar pattern as this first picture, but slightly less hard/shinny contact . That's were I stopped last night. I'll repeat the process again.

What is a reasonable expectation for repeatability for this thing if it is fixed and working properly? I've been checking the runout inside the taper that the collets engage on the chuck. Assuming I mount it in the same camlock position should I be back under .0001" every time?

Thanks