- Joined

- Mar 27, 2022

- Messages

- 485

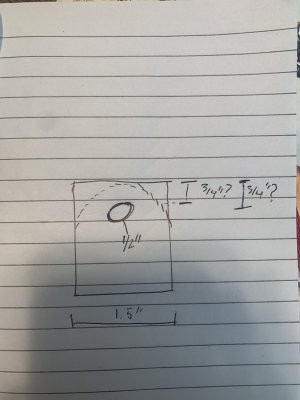

I’m wanting to make some tie down flags for a thing I’m making. They are 1.5” flat steel with 1/2” hole in it. I want to round the end of the flags with the rotary table. I get in my mind how it will work. I just don’t know how to offset it.

This is my thoughts on how to do it. Center quill up with rotary table center. Center hole in flag piece with rotary table center. Move end mill to side of part still in line with hole in one axis. Rotate table to cut.

Another question comes in also like if I want the hole centered in there should it be 3/4” back from the end?

In my head this word soup makes sense. If it’s not making sense to the rest of the world let me know and I’ll sketch it out real quick.

This is my thoughts on how to do it. Center quill up with rotary table center. Center hole in flag piece with rotary table center. Move end mill to side of part still in line with hole in one axis. Rotate table to cut.

Another question comes in also like if I want the hole centered in there should it be 3/4” back from the end?

In my head this word soup makes sense. If it’s not making sense to the rest of the world let me know and I’ll sketch it out real quick.