-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Naval Artillery Dummy Shell Refurb!

- Thread starter Weldo

- Start date

Interesting discussion here, somewhat along my prior area of expertise...

In the US Navy, my job (or "rating") was a FTG, a "Fire Control Technician, Guns" and was the start of my career in various aspects of the computer industry. Despite the "Guns" part of my rating, I served in the early 1970s, on nuclear attack submarines (Permit (Ex-Thresher) class, these boats were designed and built in the 1960s, back when digital computers were large, slow, and fragile.

Our fire control system, for torpedos (and a special antisubmarine rocket), was a hybrid of technologies which formed an analog computer system. Why analog? Purely digital computing was said to be too slow where real-time answers where needed as the situation changed.

In submarine fire control, there were three main areas of functionality,

1) Target motion analysis (TMA)

This is determining a target's course, speed and range, based on limited sensor data. And as part of the Fire Control Tracking party, we performed TMA calculations using the combined power of the human eye and brain. We were assisted by an electro-mechanical plotting table.

BTW, we had also a purely digital electronic computer in our system, used to assist in the TMA. It was all discrete component technology, with 19Kbits of memory and no disk storage.

2) "Angle Solving" The essence of submarine fire control is "gyro angle:" Based on our TMA solution, and the type of torpedo (missile) selected, are we in range to fire? And exactly what angle must the weapon, after firing, turn through to put it on course to intercept the target? These were continuously evaluated with the hybrid of mechanical/electrical/electronic analog computing.

3) Weapon control

Before firing there are several parameters that must loaded into the weapon before firing: gyro angle, distance, running depth, and perhaps sonar search settings. Some torpedoes can be wire-guided, updated with changes after firing. These are sent electronically over the wire.

Fire Control and Hobby Machinists: some common ground

As hobby machinists, we know about mechanisms with moving parts. Having to check alignment, wear, backlash, calibration, ... just like the job of us FT used to be. Now it's virtually all digital electronics.

We had a myriad of interesting components, like syncros and servos, ball-disk integrators, electo-mechanical resolvers (for trigonometric calculations), zero-backlash gear trains, precision amplifiers, and mechanical analog-digital/digital-analog converters. Maybe some of these are found in CAM machines. Now it's virtually all digital electronics.

Greg, ex-FTG1(SS)

In the US Navy, my job (or "rating") was a FTG, a "Fire Control Technician, Guns" and was the start of my career in various aspects of the computer industry. Despite the "Guns" part of my rating, I served in the early 1970s, on nuclear attack submarines (Permit (Ex-Thresher) class, these boats were designed and built in the 1960s, back when digital computers were large, slow, and fragile.

Our fire control system, for torpedos (and a special antisubmarine rocket), was a hybrid of technologies which formed an analog computer system. Why analog? Purely digital computing was said to be too slow where real-time answers where needed as the situation changed.

In submarine fire control, there were three main areas of functionality,

1) Target motion analysis (TMA)

This is determining a target's course, speed and range, based on limited sensor data. And as part of the Fire Control Tracking party, we performed TMA calculations using the combined power of the human eye and brain. We were assisted by an electro-mechanical plotting table.

BTW, we had also a purely digital electronic computer in our system, used to assist in the TMA. It was all discrete component technology, with 19Kbits of memory and no disk storage.

2) "Angle Solving" The essence of submarine fire control is "gyro angle:" Based on our TMA solution, and the type of torpedo (missile) selected, are we in range to fire? And exactly what angle must the weapon, after firing, turn through to put it on course to intercept the target? These were continuously evaluated with the hybrid of mechanical/electrical/electronic analog computing.

3) Weapon control

Before firing there are several parameters that must loaded into the weapon before firing: gyro angle, distance, running depth, and perhaps sonar search settings. Some torpedoes can be wire-guided, updated with changes after firing. These are sent electronically over the wire.

Fire Control and Hobby Machinists: some common ground

As hobby machinists, we know about mechanisms with moving parts. Having to check alignment, wear, backlash, calibration, ... just like the job of us FT used to be. Now it's virtually all digital electronics.

We had a myriad of interesting components, like syncros and servos, ball-disk integrators, electo-mechanical resolvers (for trigonometric calculations), zero-backlash gear trains, precision amplifiers, and mechanical analog-digital/digital-analog converters. Maybe some of these are found in CAM machines. Now it's virtually all digital electronics.

Greg, ex-FTG1(SS)

- Joined

- Sep 7, 2019

- Messages

- 674

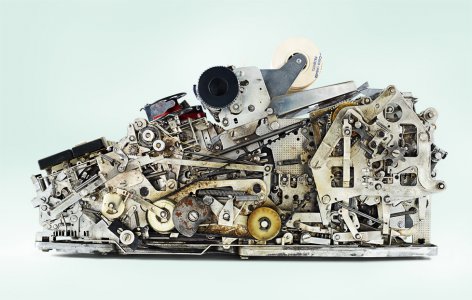

Cool! This is some neat stuff. I once saw a video showcasing a mechanical calculator, it had a dizzying amount of levers and pivoting mechanisms. Figuring all that out is nothing short of miraculous!

Would it be accurate to say that most of mechanical computation is handled by gear ratios in various ways?

Would it be accurate to say that most of mechanical computation is handled by gear ratios in various ways?

Last edited:

- Joined

- Sep 7, 2019

- Messages

- 674

Weldo,Cool! This is some neat stuff. I once saw a video showcasing a mechanical calculator, it had a dizzying amount of levers and pivoting mechanisms. Figuring all that out is nothing short of miraculous!

Would it be accurate to say that most of mechanical computation is handled by gear ratios in various ways?

From my Fire Control Tech days (50 years ago), I can't recall any purely mechanical multiplication done by gear ratios. Our calculations required smooth, continuously-variable input and output values: i.e. real numbers rather than the discrete values of fixed gear ratios. Much of the mechanical action were related to inputs to the computation, or a way of outputting the results of computation.

The Fire Control System's Attack Director section, which does the Target Motion Analysis (TMA) is a good example. It has several electro-mechanical modules, e.g. Own Ships Course, Own Ship's Speed, Target Course, Target Speed, Target Bearing, Target Range are both inputs and output devices. The modules might receive an manual input via a handcrank, or by electronic input via a "synchro-servo", in either case this causes some shaft rotation driving a dial (like a compass rose) or mechanical counter (like an odometer) providing a visual ouput for display as well as turn a shaft geared to a precision variable resistor to be used in analog math calculations.

As a purely hypothetical example, a given shaft position in the Target Range module might equate to 8,200 yards and result in a 8.200 volt output from the resistor. So the voltage is analogous to the range and would be one of several inputs to a precision OpAmp (operational amplifier) that could be used to multiple the variable range by other variables and/or constants.

One place where purely mechanical computation is done is via a device known as a "ball-disc integrator." Rather than describe it myself, here is a link explaining the hardware and the mathematics involved. Singer Librascope Ball and Disc Integrators. These devices are analogous to continuously-variable transmissions rather than manual gearboxes. Our submarines' fire control systems were built by Singer Corp's Librascope division. (Singer made more than sewing machines.]

Here's an article specific to "my" Mk113 Mod 9 UWFCS (Actually, on our 594-class fast attack subs, we had the Mod 6 system. The Attack Director section is the top section of the wide stack on the left. You can see the six black hand knobs. When one is pulled out, automatic input is disabled and you can manually set a value, push it in and the knob is disconnected and the servo motors drive the module to an externally provided value (e.g. target bearing provided by sonar or from the periscope, or by the computed value (if in the dynamic "On Torpedoes Mode.")

Greg ex-submarine Fire Control Tech, FTG1(SS).

Last edited: