- Joined

- Feb 25, 2021

- Messages

- 3,273

I'm retired, and still suffer from the same limitation.The production environment is a hunt and peck method, based on my limited free time.

I'm retired, and still suffer from the same limitation.The production environment is a hunt and peck method, based on my limited free time.

Trying to do too much is my problem too. Plus I’m pretty damned sure that I have a case of attention deficit disorder . It explains a lot about my past behavior. Plus explains all of these 1/2 “ butt” projects that I started but haven’t finished.Had to take a break. I got in that mood where I tried to get too much done.

A hobby machinist needs to be precise and take his/her time.

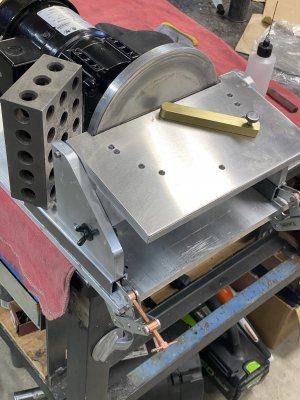

I made some mistakes this afternoon. I was surface grinding the platen and moved the wheel in the wrong direction. Ugh, I’ll fix it tomorrow.

The project will recover and the parts will be ok but it’s a good reminder.

I’m learning.

Before I go any furthe, I wanted to make sure it does what I want it to do.

I’m pretty happy with it. After using it to sharpen some HSS and carbide tools, I have changed the drip pan design.

Good questions.How does the HP and RPM combination feel?

I ebay'd a gearbox motor yesterday. Will be starting a build shortly! Let me know if you have any thoughts on design improvements as you use it. Where are you getting the diamond wheels from?Good questions.

Plenty of power for what I’ve done so far.

I’ve only used a friends diy Glendo and an Accufinish on scraper carbide blades.

I think it will be just fine.

I plan on adding another table pivot hole on each side so I can use the full diameter of the wheel.

I think a lot of the time I’ll use this free hand to touch up edges of lathe/mill tools.

I have a Baldor tool room grinder but don’t use it much for some reason.

I have a diamond wheel and a green aluminum oxide Wheel mounted right now.