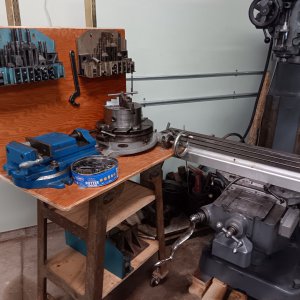

It seems so obvious now. I've been storing my rotary table with it's huge stepper motor on the bottom shelf on plywood. It has to be pushing 100#.

Each time I need it I have to drag it off that shelf to lift it onto my mill.

Storing it on a furniture dolly under the shelves is too obvious. Now it rolls right out and up to the mill.

Now I want to make a makeshift mini crane that clamps on the table to lift the rotary table.

Each time I need it I have to drag it off that shelf to lift it onto my mill.

Storing it on a furniture dolly under the shelves is too obvious. Now it rolls right out and up to the mill.

Now I want to make a makeshift mini crane that clamps on the table to lift the rotary table.