Thank you all.

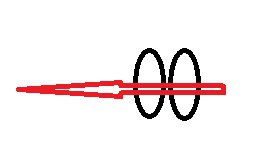

I may be closing in on it. I took the collet chuck off and apart and cleaned it in the solvent tank. While it was off I again checked the spindle runout internally. No detectable runout with the Intrapid. Put the collet chuck on and checked it. Runout of about .002. Put the ground precision rod it. Turned by hand. Same problem 5-6 thou over eight inches.

Off with the collet chuck and on with the 3-jaw. Put the aluminum bar back in. Skim cut makes it look good, very little runout over 8".

I've been working on this for two hours and need a break. I'll get back later to take another cut. Right now I'm thinking the collet chuck may be the culprit. However with the 3-jaw and dog I'm not cutting close to the tailstock as I was with the collet chuck.

To be continued...

I may be closing in on it. I took the collet chuck off and apart and cleaned it in the solvent tank. While it was off I again checked the spindle runout internally. No detectable runout with the Intrapid. Put the collet chuck on and checked it. Runout of about .002. Put the ground precision rod it. Turned by hand. Same problem 5-6 thou over eight inches.

Off with the collet chuck and on with the 3-jaw. Put the aluminum bar back in. Skim cut makes it look good, very little runout over 8".

I've been working on this for two hours and need a break. I'll get back later to take another cut. Right now I'm thinking the collet chuck may be the culprit. However with the 3-jaw and dog I'm not cutting close to the tailstock as I was with the collet chuck.

To be continued...