-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Monarch 10ee round dial Repair

- Thread starter vettebob

- Start date

- Joined

- Sep 3, 2011

- Messages

- 478

Bob,

Looks great! Is that a metal flake paint?

Cal

Looks great! Is that a metal flake paint?

Cal

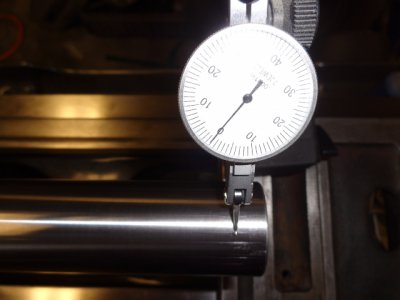

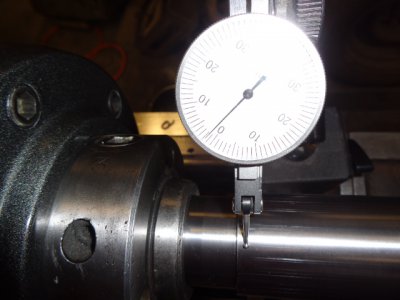

I ground the tailstock base and installed bronze shim stock. The base was worn .026 with most of the wear at the front.

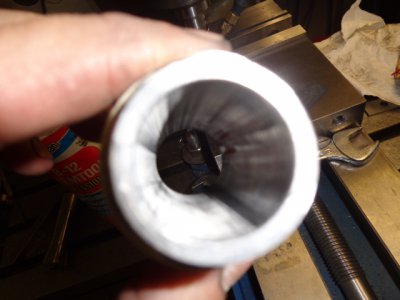

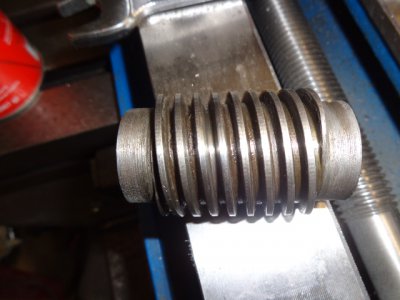

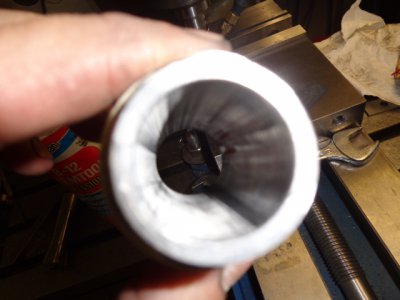

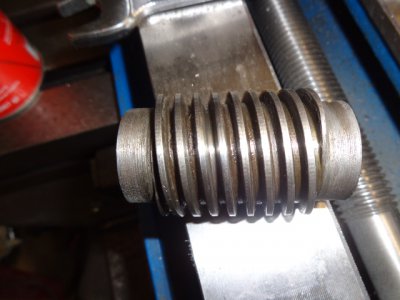

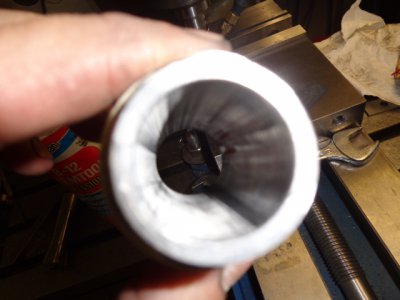

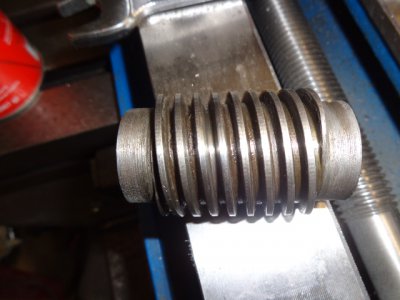

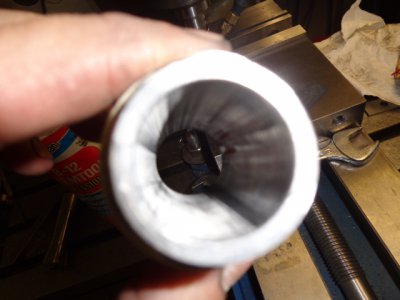

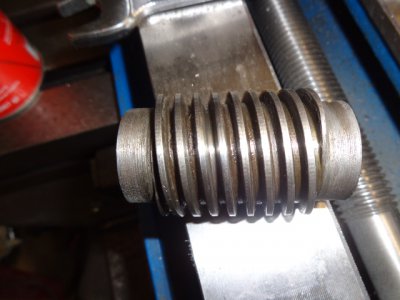

Rebuilt the worm gear. The internal key was worn by over .060 and the gear had .020 oval wear inside. I bored the gear to .874 then took a piece of .875 by .065 wall tube bored it to .753 and cut a 3/16 key way in it. The new feed shaft is .749. The key was welded to the sleeve then the sleeve was pressed in with locktite 609 bearing adhesive. I will drill and install a set screw on each end the weld the screw to prevent movement.

Rebuilt the worm gear. The internal key was worn by over .060 and the gear had .020 oval wear inside. I bored the gear to .874 then took a piece of .875 by .065 wall tube bored it to .753 and cut a 3/16 key way in it. The new feed shaft is .749. The key was welded to the sleeve then the sleeve was pressed in with locktite 609 bearing adhesive. I will drill and install a set screw on each end the weld the screw to prevent movement.