Alberto, if your goal was to measure the flatness of your table, you now have some good information. If your goal is to tram the spindle to the table, ie make sure the spindle is square to the table, you are not there yet. I apologize for not clearly understanding what you are trying to achieve.

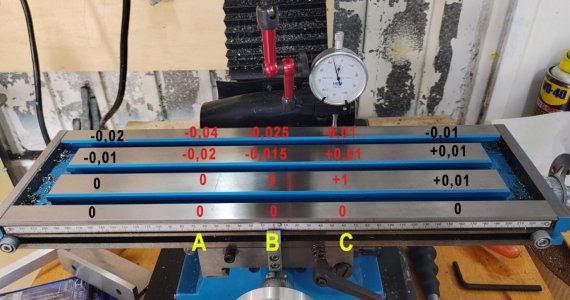

If you have been traversing the table across its X axis and Y axis travel limits, you have measured any variations in the table surface relative to the mechanical motion of your indicator. Assuming your setup is rigid, in the first picture with the red numbers, you have discovered that your table is higher on the left side (of the image) of the x axis, and is your table is higher to the rear of the table on the y axis. These numbers seem acceptable to me relative to the distances you are reading across.

To tram the table, you will need to measure differently.

If you have been traversing the table across its X axis and Y axis travel limits, you have measured any variations in the table surface relative to the mechanical motion of your indicator. Assuming your setup is rigid, in the first picture with the red numbers, you have discovered that your table is higher on the left side (of the image) of the x axis, and is your table is higher to the rear of the table on the y axis. These numbers seem acceptable to me relative to the distances you are reading across.

To tram the table, you will need to measure differently.