- Joined

- Feb 1, 2015

- Messages

- 9,983

I had thought about building a spindle mounted microscope for the Tormach for some time. The idea was to cannibalize and old phone or adapt a webcam camera but the optics was rather daunting some the project was shelved.

About a month ago, I saw an ad for a USB 50 - 500X microscope on eBay for $13.99 , including shipping. For the cost of lunch for two at McD's, it was worth a shot. The microscope came in a week ago and, after checking it out, I began designing the adapter.

The microscope would have two primary functions. 1. With the use of the DRO in Mach 3, it would in fact create a low cost optical comparator. and 2. If the microscope were concentric with the spindle axis, it would provide a means for optically locating a part feature prior to machining.

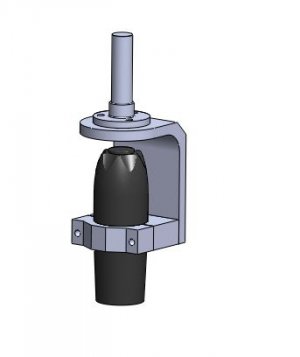

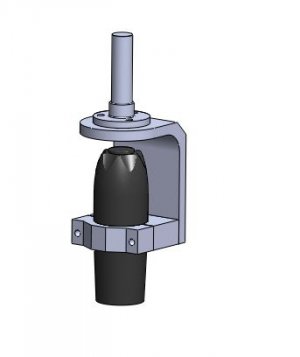

The idea was to dedicate an R8 1/2" end mill holder to the microscope. Since the R8 adapter is keyed to the spindle, the microscope will always install with the same orientation. The adapter would be adjustable to allow centering the microscope axis with the spindle axis. A clamping mechanism was first designed . An L shaped bracket was attached to the clamp and a flange with a 1/2" shaft attached to it by means of three oversized holes to allow for adjustment. Aluminum was used for all but the shaft which was made from stainless (OMC outboard motor drive shaft).

The microscope was assembled and mounted in the Tormach spindle. An old laptop provided the user interface. By rotating the spindle, the image would rotate and a feature was moved to be at the center of the rotation. That feature would then be directly in line with the spindle axis. The camera adapter was then adjusted to bring that feature to the approximate center of the screen and the adjustments locked down. This was done on the highest magnification setting. For alignment, virtual crosshairs would be ideal but the provided software did not have a feature like that for real time images so initially, the plan is to print a set of crosshairs on a transparency and tape the overlay on the screen.

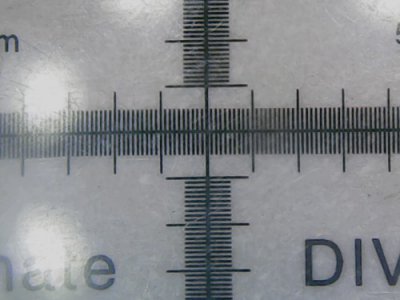

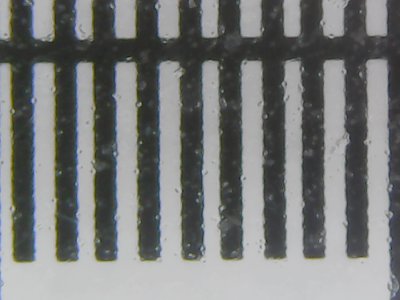

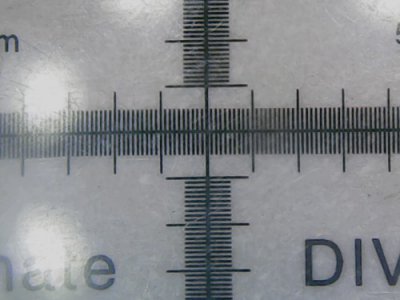

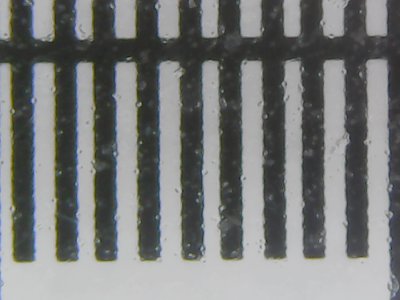

In the lowest magnification setting, the field of view is 8.8 x 6.5 mm. On a 15" monitor, this is equivalent to a magnification of 35. On the highest magnification, the field of view is .97 x .72mm, which is equivalent to a magnification of 300. I am able to resolve movements of .0001" (2.5 microns) at the highest setting, which is the smallest incremental movement that I can make in Mach 3. The bubbles in the hi res. image are imperfections in the comparator supplied with the microscope for calibration.

Edited to correct the price from $123.99 to $13.99. 8/30/2015 22:31

Bob

About a month ago, I saw an ad for a USB 50 - 500X microscope on eBay for $13.99 , including shipping. For the cost of lunch for two at McD's, it was worth a shot. The microscope came in a week ago and, after checking it out, I began designing the adapter.

The microscope would have two primary functions. 1. With the use of the DRO in Mach 3, it would in fact create a low cost optical comparator. and 2. If the microscope were concentric with the spindle axis, it would provide a means for optically locating a part feature prior to machining.

The idea was to dedicate an R8 1/2" end mill holder to the microscope. Since the R8 adapter is keyed to the spindle, the microscope will always install with the same orientation. The adapter would be adjustable to allow centering the microscope axis with the spindle axis. A clamping mechanism was first designed . An L shaped bracket was attached to the clamp and a flange with a 1/2" shaft attached to it by means of three oversized holes to allow for adjustment. Aluminum was used for all but the shaft which was made from stainless (OMC outboard motor drive shaft).

The microscope was assembled and mounted in the Tormach spindle. An old laptop provided the user interface. By rotating the spindle, the image would rotate and a feature was moved to be at the center of the rotation. That feature would then be directly in line with the spindle axis. The camera adapter was then adjusted to bring that feature to the approximate center of the screen and the adjustments locked down. This was done on the highest magnification setting. For alignment, virtual crosshairs would be ideal but the provided software did not have a feature like that for real time images so initially, the plan is to print a set of crosshairs on a transparency and tape the overlay on the screen.

In the lowest magnification setting, the field of view is 8.8 x 6.5 mm. On a 15" monitor, this is equivalent to a magnification of 35. On the highest magnification, the field of view is .97 x .72mm, which is equivalent to a magnification of 300. I am able to resolve movements of .0001" (2.5 microns) at the highest setting, which is the smallest incremental movement that I can make in Mach 3. The bubbles in the hi res. image are imperfections in the comparator supplied with the microscope for calibration.

Edited to correct the price from $123.99 to $13.99. 8/30/2015 22:31

Bob

Last edited: