- Joined

- Dec 18, 2019

- Messages

- 7,430

Better than nothing but I would probably go about 1/16". The bigger the better because it is adding strength to the part and distributing the stress to a larger area. Did you catch the editing that I did to my other post?

Richard

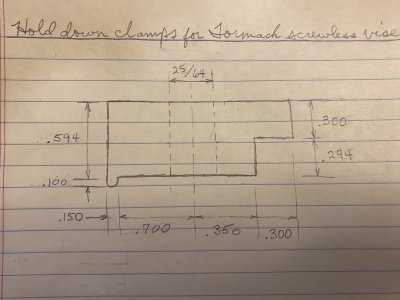

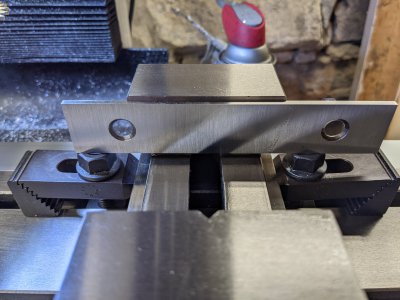

I have a real mill hold down in front of me. It's about 2.5" long, 1" wide and 0.5" thick (one of my smallest ones). I need to have the far end of the hold down on a pedestal, or one of those stepped triangle spacers. Was hoping for something more compact than that. If that's not possible, might as well get a couple more shorties (2.5") and use them instead. Can always use more general purpose hold downs. Only place I have been able to find these short ones for 3/8 studs is at McMaster. They are $9.35 each. Of course I could always use longer ones as well.Also, make the clamp longer, the short distance from the end to the hole will cause all the clamping pressure to it clamp the table with the vise acting as a step block.

So you solved my problem. I'm still going to see if I can come up with something more compact and single piece. Not sure that I can with the stock I have. A wag on this I need 1" x 1" stock. Mill an "L" with radius corners, drill holes, maybe radius the part that contacts the table. Much easier design. Ordered the 1x1 off eBay.

In the mean time, I'll just use the vise...