I'm doubly disabled , as I've got older I cannot do as much nor am I as able to move & lift many things . To keep on gardening for food , pleasure & gentle exercise I designed a plant pot system that will see me turn my toes up and still be going strong. The idea was to use minimum effort and as little material compost etc. as I could get a way with .

The first phase was plant pots made from spare 3 " square rainwater down pipes, cut in four inches in lengths and plugged with a 3/4 " thick open cell rigid foam plug

This worked well, for I can stand the compost filled seed growing pots in trays without them tipping over,so allowing me to carry a tray in my right hand whilst using my left crutch to get about .

A few years ago things went even more pear shaped , I found I could not carry the tray's when full . Moving around was becoming even more difficult so using smaller trays was not really an option for it would mean double the journey's from my second man cupboard ( A quality dwellable wooden log cabin ) to the glasshouse or around garden .

I came up with the idea of using smaller tubes but this time use round tubes so in the end things would be even lighter .

Initially I used square chunks of the open cell rigid foam for the plug but found that there was a tendency for the foam to die or the roots to grow deep into it . Tearing the roots free of the foam usually knocked the plants back by a couple of weeks or so .

I experimented with some ( rigid closed cell foam ) unwanted caravan floor awning inter locking panels . It worked well, no root problems and no degradation of the foam . However cutting the foam in squares gave a pathway for the roots and was also not very satisfactory as it often popped out as well as being a bugger to insert correctly.

I can get 33 seed tubes in each standard seed tray against ten of the square pots ( I will still use the square pots for things like bean & curbit plants ).

This is a part cut up sheet of the interlocking awning flooring

I made my cutting tool and got a perfect fit in the tubes, not too easy nor to hard to insert , especially if I pushed the tube down over the insert when it is laid on a table top .. I have 350 of these tube pots ( made from fire damaged kitchen sink waste water pipes from off the local Freecycle scheme ) with another 400 or more planned ( I might have to buy this though ).

A cut out disk showing a central line up /drain hole in the middle

This blurry picture shows the disk inserted in the end of a 40 mm ID tube that is 75 mm tall .

The beauty of this set up is that the trays are now about 2/3 less in weight than the trays with square tubes . The plants don't suffer any retarding in their growth for I use a plunger peg set in a small board to push the now core of compost and plant roots up out the tube without disturbing the root ball .

Now that I cannot bend over much or kneel easily or get back up I have to do most things standing up as straight up as I can whilst using the left a crutch for support .

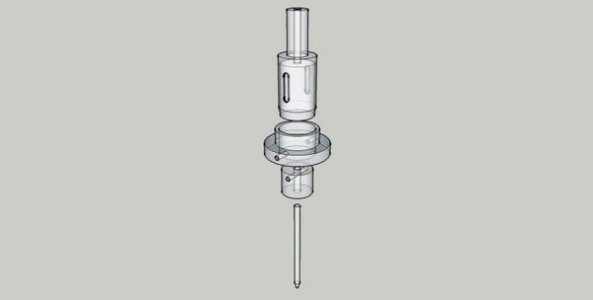

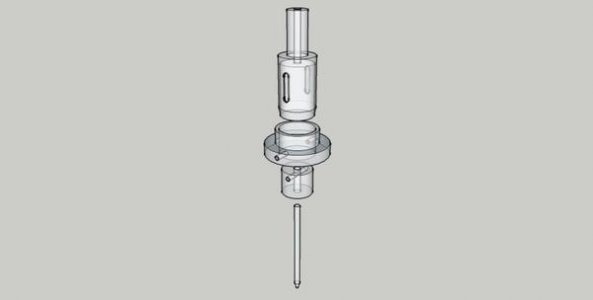

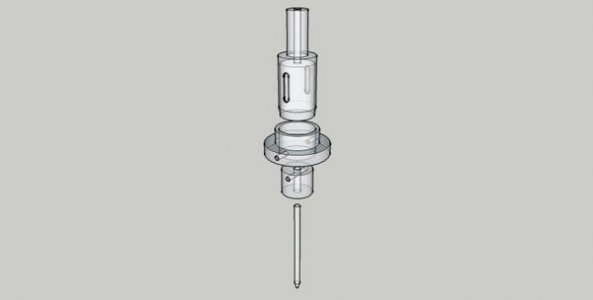

To this end I have a 50 mm ID tube that can be taped to my left crutch so that I slide the smaller plant & root ball plug down into a prepare hole in the ground level beds.

This now means that I can now consider having lots of tender annual plants/bulbs in the ground level beds as I can now easily plant them as individual plants .