- Joined

- Feb 27, 2014

- Messages

- 2,274

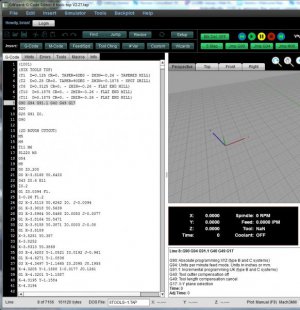

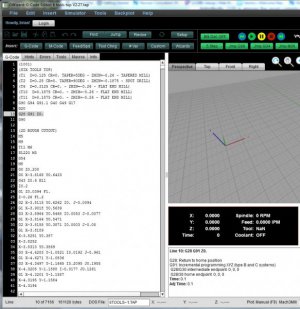

I just re-zero Z everytime I change tools. It only takes 60-120 seconds. Not good if I was in a production shop where time is money but keeps life simple with not having to deal with tool offset tables.

Mach 3 has a Z-Inhibit setting that you can set to make the minimum travel for Z. This is useful for validating new g-Code.

I often set it to something like 1.0 on the first run. this way it will follow the g-Code in every way except it will never get lower than 1 inch above Z-Zero. Then if all looks good, I might run it with Z-Inhibit at 0.1 for a final check. If you really don't trust your code, you can also set X and Y to an empty area of you table and be able to see all of the z-travels while still cutting air.

BTW, I learned this technique AFTER buying a replacement end mill

Good Luck.

one option is to break the 5 hour run into multiple operations and gcode files. This will also make it easier if you have to stop for some reason and start over. It might take a little longer when you are doing the CAM work but at the Mill, it only takes a few seconds to call up the next G-code file and start it running.Not sure I want to run the whole thing while watching, it's probably 5 hours.