-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Looking for a Slitting saw arbor

- Thread starter Ken from ontario

- Start date

- Joined

- Dec 26, 2016

- Messages

- 2,108

Alan, I have a 36" long piece of 1.5" thick CR11/14 that I thought I could use but the problem is ,it's hex shaped but I need to remove 1/4" from it anyway to get it close to the desired diameter for the arbor, it is very nice to machine with my mini lathe/mill, so far that's all I have used in steel, the rest of my projects are all Aluminum, I have not tried stainless steel or tool steel or any other harder materials with these small machines.Ken, I would suggest you buy some decent machining material. There's lots of turning, facing, and boring going on here and finish is very important.

Edit: missed your post above where you mention Stressproof

- Joined

- Dec 20, 2012

- Messages

- 9,422

Ken, hidden inside this reasonably priced 1.5" OD piece of 1144 is your arbor: http://www.ebay.ca/itm/1144-RD-CARB...326831?hash=item48a48ca82f:g:d1AAAOxy8F1RFcUe

1144 machines nicely. Your inserted carbide tools will cut it, as will your square tool. It bores nicely with an inserted carbide boring bar and drills and taps nicely as well. If you rough at lower speeds you'll be fine. If you finish at the highest speeds your lathe will run at, it will give you a really nice satin finish. Easily one of my favorite steels. Try it; you will like it.

1144 machines nicely. Your inserted carbide tools will cut it, as will your square tool. It bores nicely with an inserted carbide boring bar and drills and taps nicely as well. If you rough at lower speeds you'll be fine. If you finish at the highest speeds your lathe will run at, it will give you a really nice satin finish. Easily one of my favorite steels. Try it; you will like it.

- Joined

- Dec 26, 2016

- Messages

- 2,108

Thanks Mike for the link ,(It's worth having a piece like that around if the price was right or if the seller would ship to Canada). I already have started machining my CR11/14 and loved how fast I got rid of the hex edges,it machines very nicely even with a small lathe. I used my HSS grooving bit for interrupted cut/ roughing, it worked very well but will use the carbide for most of the project .Ken, hidden inside this reasonably priced 1.5" OD piece of 1144 is your arbor: http://www.ebay.ca/itm/1144-RD-CARB...326831?hash=item48a48ca82f:g:d1AAAOxy8F1RFcUe

1144 machines nicely. Your inserted carbide tools will cut it, as will your square tool. It bores nicely with an inserted carbide boring bar and drills and taps nicely as well. If you rough at lower speeds you'll be fine. If you finish at the highest speeds your lathe will run at, it will give you a really nice satin finish. Easily one of my favorite steels. Try it; you will like it.

Thanks for the tips on getting the best finish.

- Joined

- Aug 26, 2013

- Messages

- 1,061

There is also a new one on ebay.ca right now that is selling for over twice what a new one costs in the US: https://www.ebay.ca/itm/Sierra-Amer...560948?hash=item2131640bb4:g:MikAAOSwk~NZ074k

See here for a new one. They might ship to Canada - maybe call or email: http://www.tool-company.com/shop/ge...rra-american-gen-purpose-reach-arbor-sa-1000/

Those are two different models though, the eBay one is ultra precision and the other a plane Jane model.

http://www.sierraamerican.com/slitting-saw-arbors/

http://www.sierraamerican.com/ultra-precision-arbor-2/

As an aside MSC's "made in the USA" arbors are actually Sierra American, I got mine there, and you can see it in the product image.

https://www.mscdirect.com/product/details/08271355 I was an Enco custom convert, so its showing me a price of $40.97

- Joined

- Dec 26, 2016

- Messages

- 2,108

I've noticed some of these arbors have T.I.R. of 0.002" and some T.I.R. 0.0004", that may account for the price difference of otherwise identical arbors.

- Joined

- Jul 2, 2014

- Messages

- 7,594

I cannot find the thread right now, but someone here on H-M posted an approach to making a slitting saw arbor that could be cut in place to accurate concentricity every time the arbor is mounted in the mill spindle. It was a great idea, and I wish I could find it now. It used the rarely heard of idea of using a milling machine as a lathe, with the cutter held in the mill vise. I wish I could find the original post to give the OP (wreck-wreck???) credit for the idea. It is brilliant. Cut a new shoulder for the blade to seat on each time you mount the arbor, using a lathe tool in the mill vise, is the gist of it. The blade will run true every time...

- Joined

- Jun 12, 2014

- Messages

- 5,076

Easier to just make your own, but I guess it depends on if you have stock readily available. I used 01 drill rod for my slitting saw. I considered buying the Sierra American arbors, but they were expensive and the lower end line has had mixed reviews. I did not want to fork out the $$ for their Ultra Precision. I have about $10 of materials in mine. I suggest you use better steel for the arbor, but if you are just using it for small thin blades, it probably won't matter. The retaining bolt can self tighten to the point that it is almost impossible to remove. Putting a spring washer under the head helps.

http://www.hobby-machinist.com/threads/slitting-saw-arbors.62413/

http://www.hobby-machinist.com/threads/slitting-saw-arbors.62413/

Like Mark, I made my own. As a matter of fact, I got my design from Mark. As always, he was willing to help me out with a sketch.

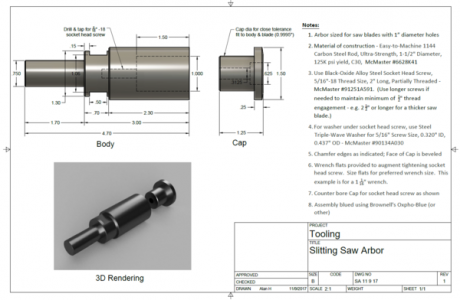

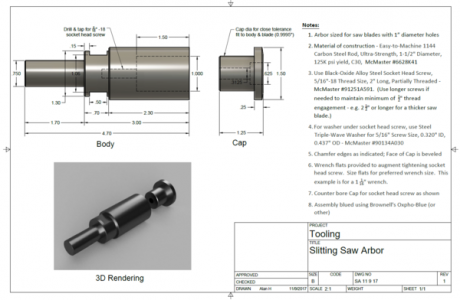

In post #14 above I attached some photos of it. I had intended to put this into Fusion and never got around to it. Decided to model it this morning and here is a drawing extracted from the model. This is one example and hopefully this will help someone make this one or gin up their own version.

A PDF of the drawing file is attached.

EDIT: revised drawing slightly, Rev. 1 now attached.

In post #14 above I attached some photos of it. I had intended to put this into Fusion and never got around to it. Decided to model it this morning and here is a drawing extracted from the model. This is one example and hopefully this will help someone make this one or gin up their own version.

A PDF of the drawing file is attached.

EDIT: revised drawing slightly, Rev. 1 now attached.

Attachments

Last edited by a moderator: