-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lead screw question.

- Thread starter Exuptoy

- Start date

- Joined

- Aug 23, 2014

- Messages

- 222

My gearbox had the same crack, left hand side, running from the "inside" corner of the g/box where it mates up to the bed(top face) to approx. halfway to the front. That led me to check alignment of the journals at either end. Couldn't see any bend/misalignment until I tried the input shaft in the full journal backwards, around 3mm/.120" off centre at the half journal. Prior to repair, very difficult to switch from one direction to other. Now, smooth as silk. A fairly agricultural repair to say the least, only measured by a rule, maybe got it under .5mm/.020".

Made a huge improvement to operation.

Made a huge improvement to operation.

- Joined

- Aug 23, 2014

- Messages

- 222

You could file the keyway, it only needs clearance. Only critical dimension for the spacer is length and if it's on the leadscrew input shaft, only one keyway required.I have quite a few 20’s and could use one but I think I’ll just turn one and get my mate to spark erode the keyway. The 24 does indeed look like the 24 without its teeth but as it didn’t look like Zamak I dismissed it.

Last edited:

Not quite correct. The spacer circumference is critical too as there is no room to use a 20/64 in the final position at the 64t screw gear as the spacer behind it fouls on the rearmost 64 compound by a few mm. I need to either make a new spacer for the end of the Screw or turn down my 24 spacer to allow clearance. I’ll try and take a pic later.You could file the keyway, it only needs clearance. Only critical dimension for the spacer is length and if it's on the leadscrew input shaft, only one keyway required.

Couldn't see any bend/misalignment until I tried the input shaft in the full journal backwards, around 3mm/.120" off centre at the half journal. Prior to repair, very difficult to switch from one direction to other. Now, smooth as silk. A fairly agricultural repair to say the least, only measured by a rule, maybe got it under .5mm/.020".

Made a huge improvement to operation.

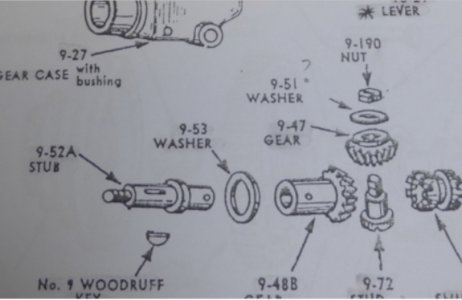

Very interesting @timmeh I’ll be sure to remove it when I replace my sliding collar yoke and check it for runout. I take it you are describing the LH side stub shaft which carries the screw (item 9-52A Stub below?)

- Joined

- Aug 23, 2014

- Messages

- 222

Yes, insert backwards, eyeball from r/h end.Not quite correct. The spacer circumference is critical too as there is no room to use a 20/64 in the final position at the 64t screw gear as the spacer behind it fouls on the rearmost 64 compound by a few mm. I need to either make a new spacer for the end of the Screw or turn down my 24 spacer to allow clearance. I’ll try and take a pic later.

Very interesting @timmeh I’ll be sure to remove it when I replace my sliding collar yoke and check it for runout. I take it you are describing the LH side stub shaft which carries the screw (item 9-52A Stub below?)

View attachment 316900

I'll measure the spacer, as long as it is small enough on the OD to clear the adjacent gear is all that matters, not necessary to be within .001".

- Joined

- Dec 25, 2011

- Messages

- 10,552

I'll add that there is a 1/4" x 7/8" roll pin holding the gear 9-48B to the stub 9-52A that was missing from the exploded view drawing in all versions of the 10F parts list. The version in Downloads has it added. Look for:

Atlas Lathe 10F-Series Parts 10L-6 Rev11.pdf 2019-07-13

Atlas Lathe 10F-Series Parts 10L-6 Rev11.pdf 2019-07-13

Cheers Robert.

Just had an email from Clausing.....they have actually quoted for a number of items that they still carry in stock. The bull gear pin and detent items, saddle gears and shafts to get rid of the backlash along with sliding collar and yoke from the reversing gearbox, Not THAT cheap but reasonable and if you wanted to bring a tired lathe back to life not too bad.

Just had an email from Clausing.....they have actually quoted for a number of items that they still carry in stock. The bull gear pin and detent items, saddle gears and shafts to get rid of the backlash along with sliding collar and yoke from the reversing gearbox, Not THAT cheap but reasonable and if you wanted to bring a tired lathe back to life not too bad.

- Joined

- Dec 25, 2011

- Messages

- 10,552

That's good news. I had heard from someone that Clausing had reduced the prices on a lot of Atlas parts. I just hope that they are not having a Fire Sale and that when current stock is sold, there will be no more.