- Joined

- Oct 7, 2020

- Messages

- 2,366

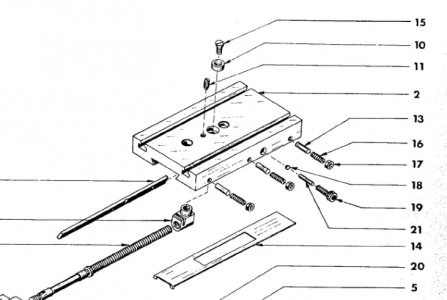

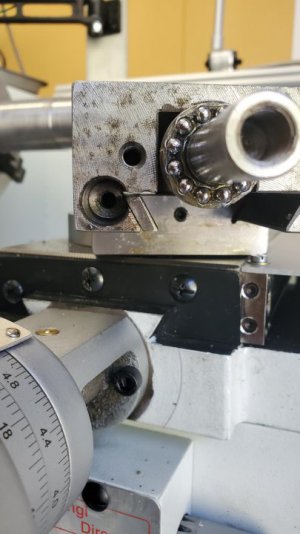

I had a little time this evening to look at the lathe. I found that there was 4 thou of movement in compound slide. I tightened it up to the point it's too tight when I crank it all the way in and 1.5 thou in the middle of the throw.

So, yesterday I didn't lock down compound, that would have helped. Tonight after I adjusted the compound gib and locked it down repeated the cut from yesterday kind of. I zeroed out like in Stefan's video and then took another 5 thousand off. This time when it got to the bigger end, it took 1/2 thousand off more then the rest of the cut. I don't know if that is acceptable or not but seems pretty good at this point.

I need to look at the gib adjustment again as it's not right. On the small end the gib the adjustment screw wants to walk over top of the end of it. If I get the gib just a little tight I can't loosen it with the other screw. It's hard to explain but I have to loosen the screw next to the hand wheel all the way out and then move the gib with a screw driver, then try and tighten it up again but not too tight. I'll call Precision Mathews tomorrow.

So, yesterday I didn't lock down compound, that would have helped. Tonight after I adjusted the compound gib and locked it down repeated the cut from yesterday kind of. I zeroed out like in Stefan's video and then took another 5 thousand off. This time when it got to the bigger end, it took 1/2 thousand off more then the rest of the cut. I don't know if that is acceptable or not but seems pretty good at this point.

I need to look at the gib adjustment again as it's not right. On the small end the gib the adjustment screw wants to walk over top of the end of it. If I get the gib just a little tight I can't loosen it with the other screw. It's hard to explain but I have to loosen the screw next to the hand wheel all the way out and then move the gib with a screw driver, then try and tighten it up again but not too tight. I'll call Precision Mathews tomorrow.