Hello all. I recently got my first lathe (SouthBend heavy 10L) from a garage.

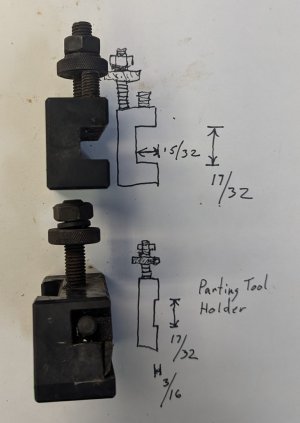

It came with a bunch of tool holders (see px) and a lot of bits, but no tool post (I think they use the "lantern" type tool post?).

Those would be tool holders for a "Lantern" tool post. Sometimes called a "Rocker" tool post.

I am struggling to understand tool holding- my "How to Run a Lathe" SouthBend book barely mentions tool posts. I also got several quick change tool posts (the piston type),

Odd to have several quick change tool posts. Can you put up a picture?

My questions are as follows:

1- will the tool bit holders shown in my picture work in my quick change tool post?

Maybe, but probably not. The bottom can be "shaved down" to change their height, and then they absolutely could. But you'd be putting a high speed steel bit into a rocker type tool holder, clamping that into a quick change holder, and attaching that to a quick change tool post......

2- if I were to purchase a lantern style tool post, how would I know if it would fit the compound slide on my lathe?

The lantern/rocker style tool post fits your tool holders, not the lathe. Of course there's limitations on how far they go, that's why that stuff comes in many sizes. But the tool holder and the tool post are matched.

What is specific to your lathe is the "T" nut that goes into the compound rest. Those can be made or bought. They're obviously obsolete by now, but there's all kinds of folks on eBay that offer up most of the common ones which will work right out of the box.

3- the shanks on the tool holders are of various sizes. Do I need a different tool post for each size of shank?

Thanks!

Maybe... In theory the tool holder matches the tool post. In practice, there's a lot of flexibility. You can also put packing (like a suitably sized high speed steel blank of an appropriate size) under the tool holder. It's also quite possible to use a packing to directly support a "larger than needed" piece of high speed steel in there, and skip the holder all together.

Before you go too far, you might want to stop and take an inventory. Rockers (lantern's) and their associated tool holders are not inexpensive. (The tooling sure is though). If you're missing parts, you might want to make a decision about getting a package together for any style that suits your fancy. Any of the common quick change tool posts, filling out your rocker post collection...

I particularly enjoy using the old rocker/lantern tool post on my lathe. But, my lathe came with a tool post, a good assortment of holders, and I added a few. The angles built into the tool holders make it MUCH faster to grind a high speed steel blank into a tool, and they're "usually" easier to get at with a stone to touch 'em up as they get some use. It's a simple "one bolt" attachment that gives you all three degrees of freedom, instantly. On the other hand... It's kind of an art. You've got to learn to pick up center. It's not hard, but you've got to learn it. Otherwise you'll go mad trying to measure it every time, as you loose that EVERY time you adjust the tool. Plus you can change tool bits with a single screw, and the angled presentation of the tool makes it VERY easy to (by hand, by eye, and by ear) bump it up or down a whisker to get it on center, above center (boring mostly) or below center if that decision becomes prudent.

A quick change tool post (of any description) will repeat the tool's position when it's removed and reinstalled. But you're going to end up with an even bigger collection of holders that take more space to store. And it's more screws and resetting center height every time you swap a tool in a holder. It will let you micromanage the height, but you're off to a second screw, just like the rocker. And it presents the tool horizontally. Way more grinding, and not so easy to touch up. It's a very good presentation angle if you're planning on using inserted tooling.

Personal opinion- The Rocker/lantern posts are not as bad as "they" say, the quick change tool posts (all of them) are hardly quicker, AFTER you've got the knack for using one, which DOES NOT come without practice and patience, and really, it's up to you. I know exactly what I would do, but it's not my new lathe, and I'm not expecting to be running it for you any time soon... So it's got to be YOUR decision. And I believe (from what you say, after we see what parts of the quick change shenanigans you've got), that from a monetary standpoint, you're "probably" at a good decision point. Kind of unfortunate that it's too soon in the game. It'd be nice if you could put together "something useful" and see what way suited you best. Although... If you're planning to run primarily insert tooling... The horizontal presentation of a quick change post will be in your best interest. There are carbide holders for the rockers, but now you're into fancy setups because you've got to get them both pointed where you want them, AND get them level... That's a chore, and the tool holders specific to that are getting kinda rare.