Hey guys lets not over think this. First--if the motor mounts like on a Bridgeport is is going to be hard to find another "C" face motor for a direct replacement. Go to the frame number on the motor tag. That number will tell you all you need to know, motor physical size, shaft size, shaft length and anything special about the keying or other shaft details. Next, try to find an old dead motor and just swap the armature. Single phase to three phase the rest of the physical dimension will probably all be different.

Yes those shafts are pressed in but are meant to stay. Try heating the whole thing in an oven and hoping the size differential between armature and shaft plus the difference in metal properties between the two will give you that extra .001" or so to get them apart. Just an idea.

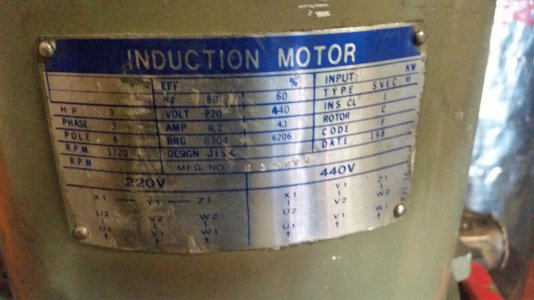

Check HP--Voltage--Frame Size--Type--Phase-- for a replacement. I have welded and re-cut shafts between centers also. Pain in the butt but doable. That is what soldered carbide lathe tools are for in my mind!

Remember, this is shop stuff, not precision rocket going to space stuff. Boo-boos and close are good enough. When the covers are back on who's gonna know? As long as it works.