-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Interesting Metal Work I have Seen

- Thread starter rwm

- Start date

- Joined

- Feb 9, 2017

- Messages

- 5,533

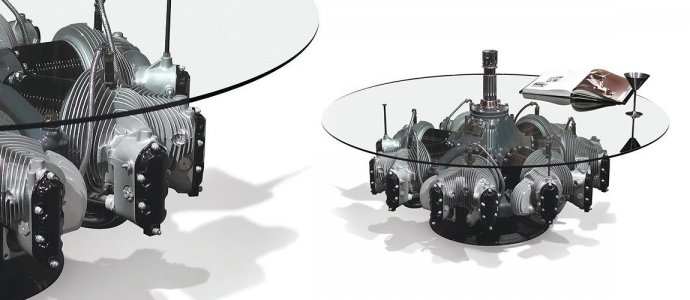

Great thread. Love this kinda stuff. In the '80's I was working as a mech in a gas station and saw a flatbed trailer with a really early radial aircraft engine on it engine mount pointing vertically. Went out and took a look and it had been turned into a coffee table with clear glass. It was so old he couldn't get it certified anymore so he converted it. I of course didn't take a pic but when I googled radial engine coffee table a bunch came up. Pinterest is full of them, but not the one I saw. Here's one, they only want $23,000 for it!

Attachments

- Joined

- Feb 9, 2017

- Messages

- 5,533

That would be a shame to put under a wood top. It has to weigh a ton, literally. I guess you wouldn't want somebody to just try to move it by the glass top though......Here's a project I'm working on with a good friend. He has a plasma table makes all kinds of signs and stuff. He wanted to get into industrial furniture and one of a kind stuff. He came up with this design which is all 1/4" plate. My job was cutting all the spacer between the plates sizing to length then cut and bore the .500 thick feet and table pads along with the 1.250 thick connection pads with 1/2 tapped holes. My friend didn't realize that drilling 1.250 holes through 8" of material was a pain and 16" of 1/2-13 tapped holes was a chore. Then the 1" holes for the feet. A lot of drilling and tapping All the spacers are stainless and we put a brushed look on them, steel plate was powder coated all hardware is zinc coated. Stainless was to much for him. Top is gonna be repurposed maple bowling lane with a clear epoxy finish 4x7 top dimensions. Might do a glass top option.

View attachment 305924View attachment 305925

- Joined

- Dec 9, 2016

- Messages

- 1,133

I dont know, In my minds Eye I can invision a split live edge plank with some nice "waterish/river" looking epoxy fills meandering the length......the entire ensemble would be reminiscent of the old railroad bridge going over the river, the kind one would jump from when they were a kid! Add some under lighting to draw attention downward and have a glowing effect to the epoxy river as seen from above.That would be a shame to put under a wood top. It has to weigh a ton, literally. I guess you wouldn't want somebody to just try to move it by the glass top though......

The glass would just lay on top of the structure on some felt pads was getting price on a pic 3/4" thick. The structure is actually five pieces legs are 2pcs each and the center section. My friend looked into the epoxy system which is really cool you can do a lot of different designs and features alittle on the pricey side if you ask me. I'm happy with natural woods with a clear or glass. Each style has its own effect on the room. I had him scale the design for a coffee table height which I'm gonna do for myself. He also was gonna make a end table version. Price point has been the biggest struggle.That would be a shame to put under a wood top. It has to weigh a ton, literally. I guess you wouldn't want somebody to just try to move it by the glass top though......

- Joined

- Jan 2, 2016

- Messages

- 1,953

The glass table I used to have, had small rubber or plastic disks. I would be afraid of felt, allowing the glass to slide. Definitely would go for glass, maybe a slight brown tint.The glass would just lay on top of the structure on some felt pads

Have you considered aluminum? having them anodized, could give you the same look, for a lot less.All the spacers are stainless and we put a brushed look on them

- Joined

- Jul 19, 2013

- Messages

- 590

...

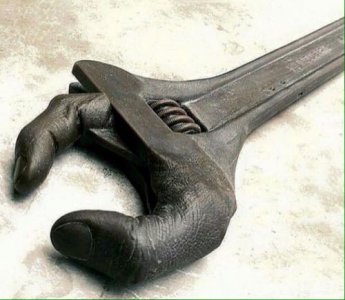

Also thought this was cool, although no longer very functional...

View attachment 305982

Very cool and artistically done.