-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Info needed for installing/setting up pm940m

- Thread starter tim81

- Start date

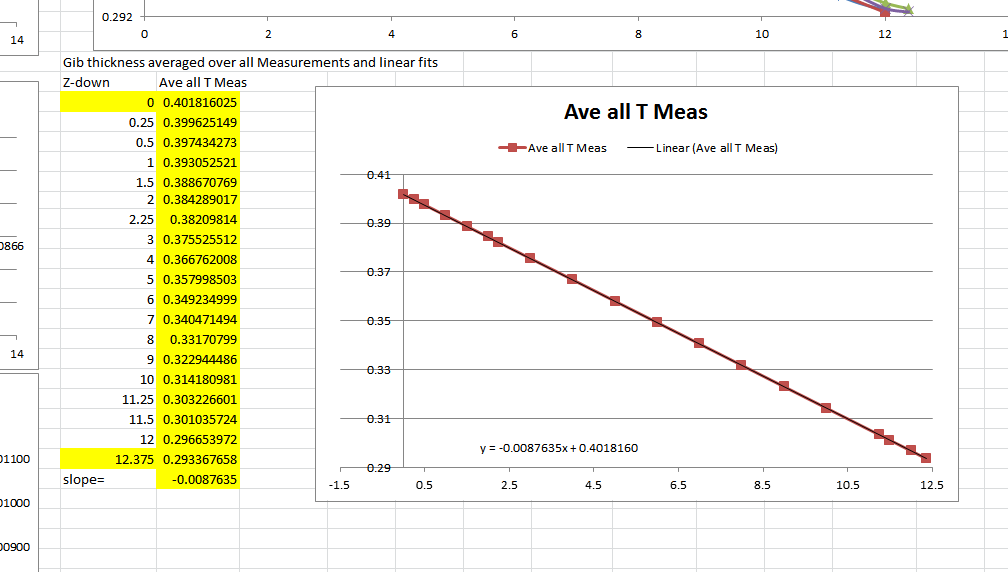

Nice pictures! Nice looking gib. A LOT nicer looking than mine. I did a lot of measurements over several days using multiple tools. I will attach a plot of some of the averages. I will be interested if you would post your dimensions. Nice to compare to mine.

I also spent a long time trying to get the dimensions of my hole so that I could make a new gib that would fit without taking the head off of the column. It is not so easy to measure the spacing in the hole, especially down inside a way from the opening. I did this by clamping the head to the column and also clamping the non-gib way side to be tight. Then I would insert thin pieces of stiff metal down into the hole diagonal and see how far it would go down. This way I could get a measure of the diagonal of the hole. Yet to finish that project!

I also spent a long time trying to get the dimensions of my hole so that I could make a new gib that would fit without taking the head off of the column. It is not so easy to measure the spacing in the hole, especially down inside a way from the opening. I did this by clamping the head to the column and also clamping the non-gib way side to be tight. Then I would insert thin pieces of stiff metal down into the hole diagonal and see how far it would go down. This way I could get a measure of the diagonal of the hole. Yet to finish that project!

I have some Mitutoyo instruments. They are nice, but a bit expensive.

Clockwise Tools, Amazon, seems to make some nice tools and are reasonably priced. I have not purchased a micrometer from them, but I have purchased digital dial micrometer (plunge micrometer) from them and it works really well. I measured it and calibrate it: 1 micron resolution and accurate to 5 microns over the full 1 inch stroke. I actually built a set up to make these measurements. I was impressed enough to purchase two more plus the cables to present the data directly into a spread sheet.

Delivered this week. ~ $65

Also, if you have not gotten one of these edge detectors you might want to. Cheap and I use mine all the time. They are especially nice if you have DRO on your machine so that you can return tot he same point.

Clockwise Tools, Amazon, seems to make some nice tools and are reasonably priced. I have not purchased a micrometer from them, but I have purchased digital dial micrometer (plunge micrometer) from them and it works really well. I measured it and calibrate it: 1 micron resolution and accurate to 5 microns over the full 1 inch stroke. I actually built a set up to make these measurements. I was impressed enough to purchase two more plus the cables to present the data directly into a spread sheet.

Delivered this week. ~ $65

Also, if you have not gotten one of these edge detectors you might want to. Cheap and I use mine all the time. They are especially nice if you have DRO on your machine so that you can return tot he same point.

Mitutoyo 050101, Edge Finder, 3/8" Dia. Shank, .200" Dia. Tip

I was thinking the same thing. Will try and get those measurements too. I will put them on a spreadsheet like yours so we can compare. With little luck can get some useful information. Keep in mind this is my first lathe so please can you and the guys here share tips thought on what I should measure. I will do the monkey work but I need someone to tell me what to measure.Nice pictures! Nice looking gib. A LOT nicer looking than mine. I did a lot of measurements over several days using multiple tools. I will attach a plot of some of the averages. I will be interested if you would post your dimensions. Nice to compare to mine.

I also spent a long time trying to get the dimensions of my hole so that I could make a new gib that would fit without taking the head off of the column. It is not so easy to measure the spacing in the hole, especially down inside a way from the opening. I did this by clamping the head to the column and also clamping the non-gib way side to be tight. Then I would insert thin pieces of stiff metal down into the hole diagonal and see how far it would go down. This way I could get a measure of the diagonal of the hole. Yet to finish that project!

View attachment 468799

Yep that’s the ones I gotI have some Mitutoyo instruments. They are nice, but a bit expensive.

Clockwise Tools, Amazon, seems to make some nice tools and are reasonably priced. I have not purchased a micrometer from them, but I have purchased digital dial micrometer (plunge micrometer) from them and it works really well. I measured it and calibrate it: 1 micron resolution and accurate to 5 microns over the full 1 inch stroke. I actually built a set up to make these measurements. I was impressed enough to purchase two more plus the cables to present the data directly into a spread sheet.

Delivered this week. ~ $65

Also, if you have not gotten one of these edge detectors you might want to. Cheap and I use mine all the time. They are especially nice if you have DRO on your machine so that you can return tot he same point.

Mitutoyo 050101, Edge Finder, 3/8" Dia. Shank, .200" Dia. Tip

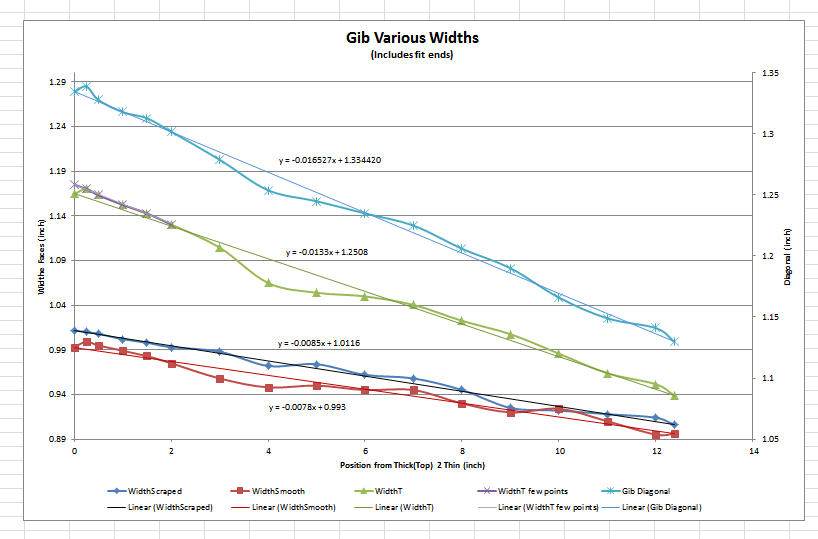

If you really go to all of this trouble also measure the wide width (sharp corner to sharp corner) a function of length. If when you put it back and you measure how much of the gib is sticking out of the hole (big end) then after some calculations you will have an idea of how big the gib hole is nominally.... Mine is the top curve in the following plot. By the way, my 940M's way corners are at 55 degree. Some other machines are at 60 degree. This relates to the side corners angles of the gib. I have to go. Have fun.

Thanks man a lot for your help. I will try to get as many measurements as possibleIf you really go to all of this trouble also measure the wide width (sharp corner to sharp corner) a function of length. If when you put it back and you measure how much of the gib is sticking out of the hole (big end) then after some calculations you will have an idea of how big the gib hole is nominally.... Mine is the top curve in the following plot. By the way, my 940M's way corners are at 55 degree. Some other machines are at 60 degree. This relates to the side corners angles of the gib. I have to go. Have fun.

View attachment 468804