- Joined

- Jan 20, 2013

- Messages

- 285

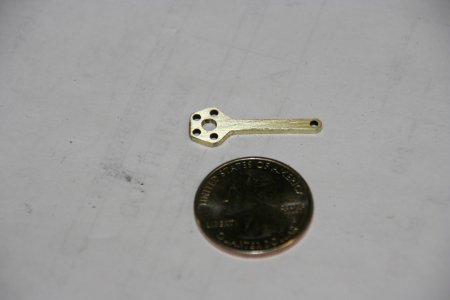

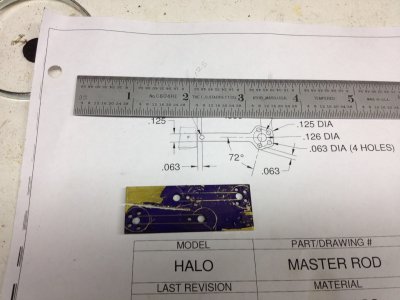

Halo Valve Plungers

The Halo uses a pair of 3/16" diameter balls as the valves for intake and exhaust. The balls seat down in a counterbored hole in the head. Air pressure (and I guess a small spring) hold them seated and prevent the air pressure (or steam) from entering or exiting the cylinder. The Valve Plungers, one shown above, displace ball from its seat allowing air to pass. The rocker arms press the plungers down when the push rods and the cam followers move them..

The plungers start out as 1/4" (.250") brass rod. I carefully turned the .125" shaft of them to be a slip fit in the .126" reamed holes in the head for them. Too tight or rough and there will be too much friction for them to move freely. Too loose and the compressed air will leak out around them and degrade performance. The head of the plunger is rounded to reduce friction with the rocker arms.

Above is a short video of how I rounded the head of the Valve Plungers. I like watching it. It does seem like I should have moved the ball turner further away before sticking my fingers in there! I used a 1/8" 5C collet with a stop in the back to hold all the plungers in the same place. I experimented with my ball turner to get a nice looking radius.

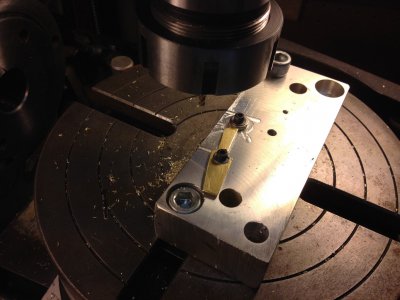

The above is "the making of the movie" photo!

Cheers

Dave

The Halo uses a pair of 3/16" diameter balls as the valves for intake and exhaust. The balls seat down in a counterbored hole in the head. Air pressure (and I guess a small spring) hold them seated and prevent the air pressure (or steam) from entering or exiting the cylinder. The Valve Plungers, one shown above, displace ball from its seat allowing air to pass. The rocker arms press the plungers down when the push rods and the cam followers move them..

The plungers start out as 1/4" (.250") brass rod. I carefully turned the .125" shaft of them to be a slip fit in the .126" reamed holes in the head for them. Too tight or rough and there will be too much friction for them to move freely. Too loose and the compressed air will leak out around them and degrade performance. The head of the plunger is rounded to reduce friction with the rocker arms.

Above is a short video of how I rounded the head of the Valve Plungers. I like watching it. It does seem like I should have moved the ball turner further away before sticking my fingers in there! I used a 1/8" 5C collet with a stop in the back to hold all the plungers in the same place. I experimented with my ball turner to get a nice looking radius.

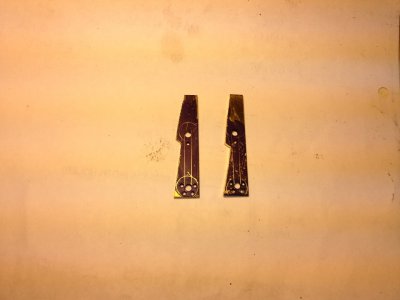

The above is "the making of the movie" photo!

Cheers

Dave

Last edited: