Running a printer is a bit of an art...

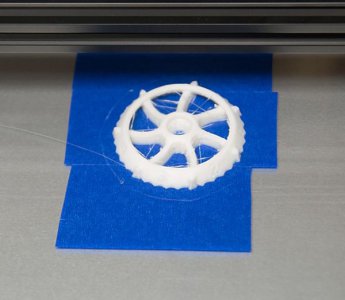

For the skirt/brim, some slicers have an option to offset it from the part, so you print an outline a few mm away from the part to prime the nozzle and such. Unless you need the extra adhesion to the bed, it is a nice option to use. Makes cleanup on the parts go a bit faster.

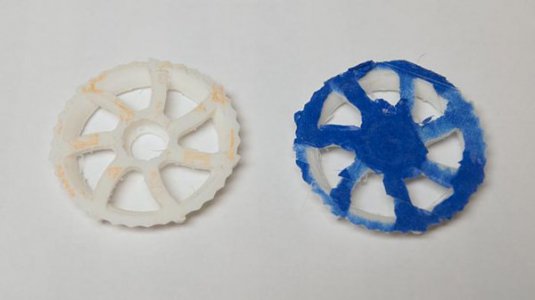

For most things, 20% infill is plenty. For gears and such, do 100%, but make sure your extrusion rate is calibrated properly or you get weird artifacts and off size prints.

Overhangs over about 45 degrees need support.

You need it to stick, but not too much.. Level the bed and adjust the starting height properly.

For most materials, a PEI sheet is a really good option. I bought mine from these guys.

http://catalog.cshyde.com/viewitems/3d-printing-materials/ultem-pei I went with a 20mil. If you need a size not listed, email them. They can make custom sizes. I like it far better than tape, hairspray, etc..

The settings in your slicer program are a bit of a rabbit hole. You can tinker almost endlessly with them to dial in settings. Don't go too nuts, unless you're making a lot of the same part.

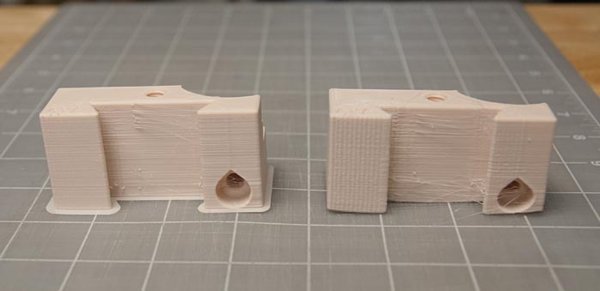

I like this test part when setting up a new filament ...

https://www.thingiverse.com/thing:1023717 It prints fast, but tests a lot of little things. Then I use pliers and bend them to test inter-layer bonds. If it falls apart all along layer lines, increase print temp. Helps to make sure you get a good solid print. Even changing colors, this can make a difference.

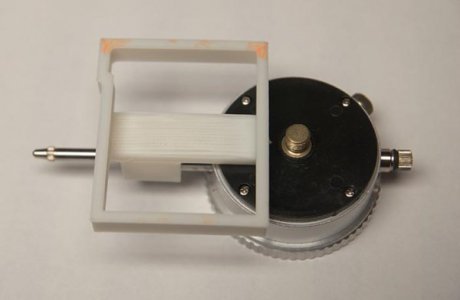

Handy lathe print for AXA toolposts..

https://www.thingiverse.com/thing:1396510

Hope some of it helps.