Well brand new to the forum but wanted to see if others have run into this problem. I recently decided to upgrade to a larger lathe with milling abilities and found a smithy granite 1340 through a friend’s friend. The machine was originally purchased for a farm and used by someone a little less familiar with machining practices as I learned from all the broken carbide tools and the toothless bevel gear at the milling arm base.

I purchased the 88.00 + 10.00 shipping nylon bevel gear from smithy and removed the milling arm. It wasn’t obvious right away but when I started to look a little closer inside the headstock to determine if I wanted to replace bearings, I noticed a crack inside the headstock right above the spindle left taper bearing.

I contacted smithy because the headstock was unorderable online and they told me that is a part they never sell. It is not stocked and I should just use the machine as is or fasten it together with a couple plates of steel. If I really wanted a new headstock casting, it would need to be hand fitted, take 4-6 weeks to order and at least $1000.00. WHAT! That’s a empty casting and that want nearly 1/4 of the cost of a new machine with tooling. That number was pulled out of the air without even looking up the part. I think it was a “make the number high enough so he won’t want it” kind of thing.

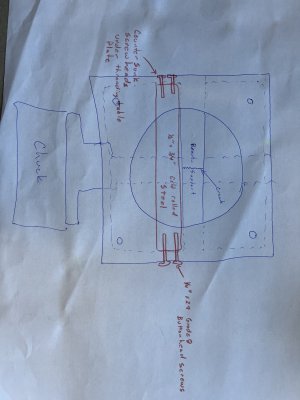

Anyway, I am thinking that a well placed piece of steel screwed and JB welded inside the headstock will remain out of the way and give the bearing support the little bit of ridgidity it lost from the crack. My plan is to totally dismantle the headstock and degrease it and soak in some evaporust to remove any surface rust. Then hand fit a 1/2” x3/4” piece of cold rolled steel so it fits infront of the bearing support. Clamp it in place and drill two 1/4” holes from front and back through the headstock into the steel ends. JB weld the three surfaces that contact the headstock and screw it in place. I figure the JB weld will take up any voids that may be left between the steel and cast and make it that much more ridgid.

What do you think. Will it work? How many granite machines do you think have a crack in this same location and it is unknown by the owner? There is less than 1/4” of casting above this bearing cup in this location.

I purchased the 88.00 + 10.00 shipping nylon bevel gear from smithy and removed the milling arm. It wasn’t obvious right away but when I started to look a little closer inside the headstock to determine if I wanted to replace bearings, I noticed a crack inside the headstock right above the spindle left taper bearing.

I contacted smithy because the headstock was unorderable online and they told me that is a part they never sell. It is not stocked and I should just use the machine as is or fasten it together with a couple plates of steel. If I really wanted a new headstock casting, it would need to be hand fitted, take 4-6 weeks to order and at least $1000.00. WHAT! That’s a empty casting and that want nearly 1/4 of the cost of a new machine with tooling. That number was pulled out of the air without even looking up the part. I think it was a “make the number high enough so he won’t want it” kind of thing.

Anyway, I am thinking that a well placed piece of steel screwed and JB welded inside the headstock will remain out of the way and give the bearing support the little bit of ridgidity it lost from the crack. My plan is to totally dismantle the headstock and degrease it and soak in some evaporust to remove any surface rust. Then hand fit a 1/2” x3/4” piece of cold rolled steel so it fits infront of the bearing support. Clamp it in place and drill two 1/4” holes from front and back through the headstock into the steel ends. JB weld the three surfaces that contact the headstock and screw it in place. I figure the JB weld will take up any voids that may be left between the steel and cast and make it that much more ridgid.

What do you think. Will it work? How many granite machines do you think have a crack in this same location and it is unknown by the owner? There is less than 1/4” of casting above this bearing cup in this location.

Attachments

Last edited: