- Joined

- Jul 18, 2017

- Messages

- 407

Hi guys,

As many of you know, I wasn't planning on buying a Bridgeport mill, but then I recently stumbled across a super deal on one. This 2J Bridgeport had been used for years at a San Jose vocational school before it ended up with the private high school that I bought the mill from. The private high school in Santa Rosa had the mill sit in an unused workshop for a year before the facilities manager was told that the students wanted to work on "new" CNC machines, and not on the old big dirty Bridgeport. To that, I still have to say, "WTF?!"

I shared the mill's history since it will explain the situation that I need help with. Also, fyi, I did try google for answers before having to turn to you wonderful guys

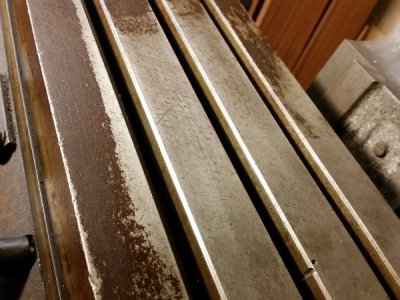

Basically, the mill is dirty and has rust on the table. It had been checked out by two separate machinists, and I was told the only thing it needed was to grease the table's leadscrews.

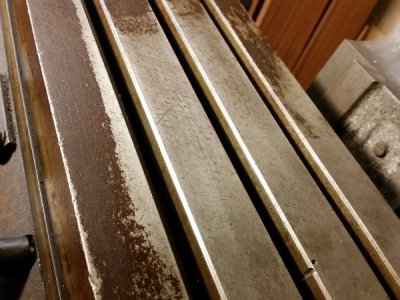

I will post various pics of the table below at different angles and with/without flash to show, what looks like, the original factory scrapings. For comparison, I will also post a pic of the ways behind the milling table that really show how the scrapings originally looked like. Btw, sorry if the pics aren't great - my cell phone camera kinda sucks.

So, in a nutshell, I'd like to know if it is possible to remove the rust without removing the scraping remnants on the milling table. Also, please tell me if I am being silly or not in wanting to preserve the scrapings.

Table

Rear ways

Front ways

The table seems unusual by that it looks like some inattentive students milled or drilled into the table a couple of times, and it looks like they dropped stuff onto the table quite a bit, yet, there are still scraping marks present. I plan on using metal filler to repair the holes/indentions, as instructed in the recent book I bought, "A Guide to Renovating the Bridgeport "2J" Variable Speed Milling Machine."

Also, I looked up the serial number. Apparently, this $450 mill was built in 1976.

Btw, I have tried Evaporust before on tools. I just don't like how it can turn the metal black. So, could I get away with using a scotch brite pad and WD-40 instead?

I will post a pic of the entire Bridgeport inside my 1 car garage later. My friend Mike, who owns a machinery transportation company, had tilted the head before using his forklift to put the mill in my garage. The head is still tilted. After I straighten the head later today, I will take some full body shots - for those of you who appreciate machine porn ;-)

Thanks in advance for your friendly replies

Susan

As many of you know, I wasn't planning on buying a Bridgeport mill, but then I recently stumbled across a super deal on one. This 2J Bridgeport had been used for years at a San Jose vocational school before it ended up with the private high school that I bought the mill from. The private high school in Santa Rosa had the mill sit in an unused workshop for a year before the facilities manager was told that the students wanted to work on "new" CNC machines, and not on the old big dirty Bridgeport. To that, I still have to say, "WTF?!"

I shared the mill's history since it will explain the situation that I need help with. Also, fyi, I did try google for answers before having to turn to you wonderful guys

Basically, the mill is dirty and has rust on the table. It had been checked out by two separate machinists, and I was told the only thing it needed was to grease the table's leadscrews.

I will post various pics of the table below at different angles and with/without flash to show, what looks like, the original factory scrapings. For comparison, I will also post a pic of the ways behind the milling table that really show how the scrapings originally looked like. Btw, sorry if the pics aren't great - my cell phone camera kinda sucks.

So, in a nutshell, I'd like to know if it is possible to remove the rust without removing the scraping remnants on the milling table. Also, please tell me if I am being silly or not in wanting to preserve the scrapings.

Table

Rear ways

Front ways

The table seems unusual by that it looks like some inattentive students milled or drilled into the table a couple of times, and it looks like they dropped stuff onto the table quite a bit, yet, there are still scraping marks present. I plan on using metal filler to repair the holes/indentions, as instructed in the recent book I bought, "A Guide to Renovating the Bridgeport "2J" Variable Speed Milling Machine."

Also, I looked up the serial number. Apparently, this $450 mill was built in 1976.

Btw, I have tried Evaporust before on tools. I just don't like how it can turn the metal black. So, could I get away with using a scotch brite pad and WD-40 instead?

I will post a pic of the entire Bridgeport inside my 1 car garage later. My friend Mike, who owns a machinery transportation company, had tilted the head before using his forklift to put the mill in my garage. The head is still tilted. After I straighten the head later today, I will take some full body shots - for those of you who appreciate machine porn ;-)

Thanks in advance for your friendly replies

Susan