- Joined

- Feb 18, 2016

- Messages

- 451

I have one of those 3-in-1 Lathe/Mill/Drill machines. I'm trying to do some light milling on it.

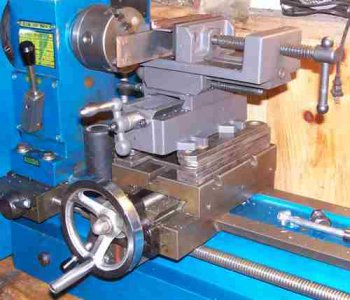

One major problem is that the table is way beneath the milling cutter. I actually bought a pretty tall X-Y vice to hold the workpieces. The main reason for buying this X-Y vice was to raise the workpiece up. But it is nice to have the X-Y adjustments too for getting things adjusted initially. I tend to lock those down then when I'm actually doing the milling and I use the Lathe Saddle for the actual feed. So far this has been working for me. But today I ran into two problems.

First let me share some photos of the set up, then I'll address the problems on the other side.

Below:

Picture of the workpiece in the vice with the mill quill fully retracted.

PHOTO A:

Below:

Picture of the workpiece in the vice with the mill quill fully extended.

PHOTO B:

As you can see the mill cutter doesn't even reach the workpiece when the mill quill is fully extended.

The problem I had when using the drill chuck was simply too much play. For one thing I couldn't even get the milling cutter to sit very deeply in the drill chuck. I'm using a double-ended mill, so it wouldn't go in the drill chuck very far. So now I've put the end mill in a MT3 collet. It fits in much further, and since there is no drill chuck it's also much higher and closer to the end of the quill. So now I can't even reach the workpiece with the quill fully extended.

Not only this, but ideally I'd like to work with the quill retracted into the milling head as far as possible. The further I extend the quill the more likely I'll run into potential problems with the cutter not being real stable.

Since there is no Z-axis on the table, I can't lift up the workpiece using a Z-axis screw. So the only thing left to do is to block up the vice. I figure I'll need to put a mounting plate between the vice and the table to lift the vice up a good 3" or so. But I don't have any steel or even aluminum blocks to use to block this up. So I'm wondering if maybe I could weld something up out of angle iron? I could then mill the finished thing flat and parallel with the mill. Since the extension block would be tall enough I could put it in the vice as is, and it would already be 3" taller.

Just curious if anyone else has any other suggestions? Also, I'm wondering if a block of oak would work in a pinch for this lightweight job for now? I have a woodshop and I could mill up a nice wooden block of oak pretty quickly. But I wonder if the wood would give and cause vibrations or chatter? I'm thinking a block of oak probably wouldn't work very well? But it is tempting since it would be a quick fix for now.

Finally, is it ok to hold a 1/4" end mill in an MT3 collet? The collet is 3/8" as is the body of the 1/4" end mill. I just bought these MT3 collets to use on the lathe, I certainly don't want to ruin one by spinning this endmill in one.

I have some ER20 collets on order to use in the Mill for holding tools, but they won't be here to the end of the month. So I was going to try using this MT3 collet for now. That is, if I can lift the work piece up to where I can mill it.

All I want to do is mill the inside corner of a piece of angle steel so that the corner is nice and square instead of rounded. This shouldn't take much milling to do this. Just basically cleaning up an inside corner.

I just need a rock solid way to lift this vice up about 3".

Any suggestions? Other than buying a real mill.

I do plan on buying a real mill someday, but that's another story entirely.

One major problem is that the table is way beneath the milling cutter. I actually bought a pretty tall X-Y vice to hold the workpieces. The main reason for buying this X-Y vice was to raise the workpiece up. But it is nice to have the X-Y adjustments too for getting things adjusted initially. I tend to lock those down then when I'm actually doing the milling and I use the Lathe Saddle for the actual feed. So far this has been working for me. But today I ran into two problems.

- I'm trying to mill a very small piece of work.

- I've eliminated the drill chuck from the mill arbor and I'm using a collet to hold the end mill.

First let me share some photos of the set up, then I'll address the problems on the other side.

Below:

Picture of the workpiece in the vice with the mill quill fully retracted.

PHOTO A:

Below:

Picture of the workpiece in the vice with the mill quill fully extended.

PHOTO B:

As you can see the mill cutter doesn't even reach the workpiece when the mill quill is fully extended.

The problem I had when using the drill chuck was simply too much play. For one thing I couldn't even get the milling cutter to sit very deeply in the drill chuck. I'm using a double-ended mill, so it wouldn't go in the drill chuck very far. So now I've put the end mill in a MT3 collet. It fits in much further, and since there is no drill chuck it's also much higher and closer to the end of the quill. So now I can't even reach the workpiece with the quill fully extended.

Not only this, but ideally I'd like to work with the quill retracted into the milling head as far as possible. The further I extend the quill the more likely I'll run into potential problems with the cutter not being real stable.

Since there is no Z-axis on the table, I can't lift up the workpiece using a Z-axis screw. So the only thing left to do is to block up the vice. I figure I'll need to put a mounting plate between the vice and the table to lift the vice up a good 3" or so. But I don't have any steel or even aluminum blocks to use to block this up. So I'm wondering if maybe I could weld something up out of angle iron? I could then mill the finished thing flat and parallel with the mill. Since the extension block would be tall enough I could put it in the vice as is, and it would already be 3" taller.

Just curious if anyone else has any other suggestions? Also, I'm wondering if a block of oak would work in a pinch for this lightweight job for now? I have a woodshop and I could mill up a nice wooden block of oak pretty quickly. But I wonder if the wood would give and cause vibrations or chatter? I'm thinking a block of oak probably wouldn't work very well? But it is tempting since it would be a quick fix for now.

Finally, is it ok to hold a 1/4" end mill in an MT3 collet? The collet is 3/8" as is the body of the 1/4" end mill. I just bought these MT3 collets to use on the lathe, I certainly don't want to ruin one by spinning this endmill in one.

I have some ER20 collets on order to use in the Mill for holding tools, but they won't be here to the end of the month. So I was going to try using this MT3 collet for now. That is, if I can lift the work piece up to where I can mill it.

All I want to do is mill the inside corner of a piece of angle steel so that the corner is nice and square instead of rounded. This shouldn't take much milling to do this. Just basically cleaning up an inside corner.

I just need a rock solid way to lift this vice up about 3".

Any suggestions? Other than buying a real mill.

I do plan on buying a real mill someday, but that's another story entirely.