- Joined

- Jul 17, 2019

- Messages

- 13

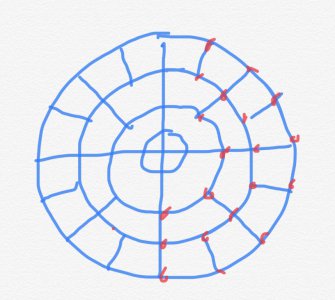

I have a 4" rotary table for my Grizzly mill. I'd like to make an 8" top plate for it so I can have room to bolt down a 4" piece. My thought is to make the top plate with as many holes as I can drill in it and still have the plate remain strong. I'm thinking 3/8" threaded holes 3/4" on centers. I would need the center hole to match up with the center hole on my rotary table and 4 holes roughly 3" around the center hole to bolt the top plate to the rotary table. What is the best way to lay out a pattern of holes 3/8" by 3/4" on centers?

My first thought is to figure out each diameter from 7.5" to 3" staying as close to the 3/4" centers as possible. 7.5" C=(2 x Pi x r) a circumference of 47.1". A spacing of .785" = 60 holes. 360 \ 60 = 6 so a 3/8 hole every 6 degrees slightly larger than 3/4". Do that for the next smaller diameter and so on. My question is, is my thinking right and is there a better way of doing it?

My first thought is to figure out each diameter from 7.5" to 3" staying as close to the 3/4" centers as possible. 7.5" C=(2 x Pi x r) a circumference of 47.1". A spacing of .785" = 60 holes. 360 \ 60 = 6 so a 3/8 hole every 6 degrees slightly larger than 3/4". Do that for the next smaller diameter and so on. My question is, is my thinking right and is there a better way of doing it?