I have an Atlas TH54/QC54 lathe, with basic tooling. (3 & 4 jaw chucks, face plate, steady rest, milling fixture etc) I have a part that I would like to face flat, but am not sure if I can do it with what I have available. The part is a cylinder head for an antique engine, about 6.5" dia, irregular shaped, with four thru-holes. I'd like to clean up the mounting/gasket surface as it was badly rusted. There is no way I can hold the part in a chuck, so my thought was to use a face plate, placing spacers to support the part on four bolts. The problem is that the bolt heads would be sitting right where I want to face the part. So is there another method to hold this? Something other than a bolt to hold the part?

Use studs instead of bolts. The studs will keep the head aligned and either a live center or live chuck ( rolling chuck) against the head .After you clean up as close as possible to the live center point, remove the head and clean the area where the point touched by hand.Even if the studs are proud of the head,face them as you do the head itself.

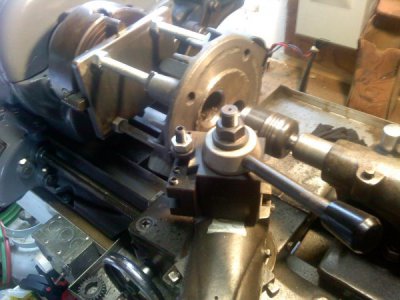

mike