-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to drill opposite holes on round stock?

- Thread starter RVJimD

- Start date

- Joined

- Aug 13, 2020

- Messages

- 1,342

The slight possibility that the flat material will get bumped when you open the vice. If you clamp the flat piece some how, it's perfect in my mind.Using your same idea...

1. Lay a piece of flat material slightly narrower in width than the diameter of the tube or bar on the bottom of the mill vise pushed up against the fixed jaw.

2. With just the flat material in the vise, clamp it, indicate off the fixed jaw half the diameter and drill a pin hole in the flat stock.

3. Open the vise, put the round stock in the vise, clamp and drill the pin diameter thru the top wall.

4. Then put the pin in the top hole, flip it over and put the pin into the hole in the flat stock in the bottom of the vise.

5. Now you can close the vise on the tube while you drill or ream it again.

Minimal set up. What's wrong with that idea?

- Joined

- Apr 12, 2018

- Messages

- 28

A vice stop could keep the rectangular stock from sliding along the jaw. Then either an adjustable parallel, piece of rubber, urethane, foam, spring or anything firm and compressible could hold it against the back jaw. Shotgun's idea of the pin gives you some options which you may need because the next time the whole situation and set up could be different and require another tweak. I can tell you that I had never considered using a pin before.

Following Shotgun's approach with what I have, you could use your hardened V blocks and clamp a piece of metal between them to the table that would almost touch the bottom of the round stock. That would give you something to drill the pin hole into. A little more clamping required but the actual part may not fit into a vise. These jobs are all about the set-ups and having options you recognize without having to create a bunch of bad parts. It's great to share ideas.

Following Shotgun's approach with what I have, you could use your hardened V blocks and clamp a piece of metal between them to the table that would almost touch the bottom of the round stock. That would give you something to drill the pin hole into. A little more clamping required but the actual part may not fit into a vise. These jobs are all about the set-ups and having options you recognize without having to create a bunch of bad parts. It's great to share ideas.

Last edited:

- Joined

- Oct 31, 2016

- Messages

- 2,720

Is there some reason why you can't drill all the way through? I recently needed 4 holes spaced equally around a tube. I centered the drill on the top of the tube and drilled all the way through. Rotated the tube 90* in the vise and drilled all the way through the tube. Done

- Joined

- Jan 29, 2017

- Messages

- 311

If you're on a mill just clamp it into a table slot and do what mickri said above. I would use a long series slot drill if drilling a common size.

Thats minimalist.

Thats minimalist.

- Joined

- Oct 28, 2020

- Messages

- 542

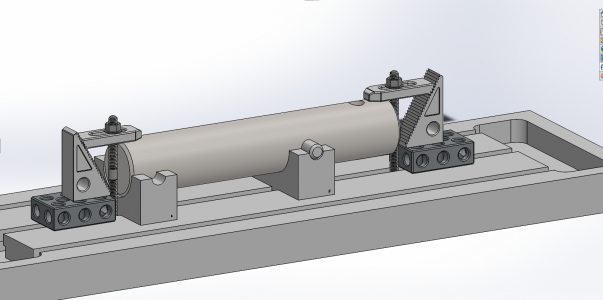

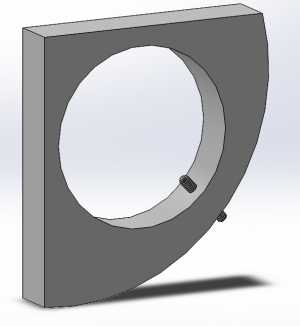

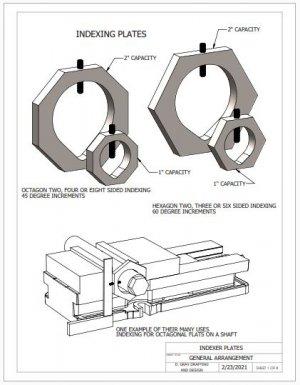

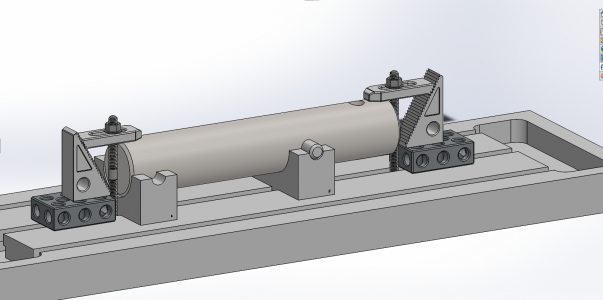

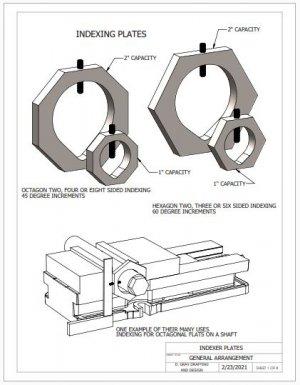

My tiny company makes tail shafts for augers. 2 7/16 diameter x 13 long with two holes 90 degrees apart. I sell two or three a month and make them up in batches of eight. How to get the holes 90 degree apart? Well not knowing better, and unable to find this thread at the time, I made up an elaborate jig. The first hole is drilled then a pin is used to register the shaft for the second hole.

This was a time consuming and tricky jig to do on my small equipment.

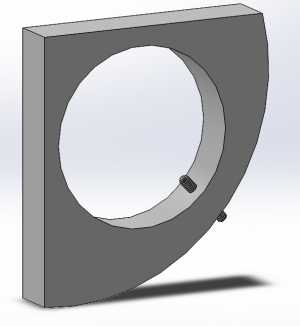

Turns out all I needed was this scrap bin indexing plate...

Clamp this on the shaft and as long as you have two 90 degree sides a square can be used to set the index plate to the mill table.

I've drawn up more elaborate indexing plate and the drawing are available at my store as a PDF digital down load for $4US.

This was a time consuming and tricky jig to do on my small equipment.

Turns out all I needed was this scrap bin indexing plate...

Clamp this on the shaft and as long as you have two 90 degree sides a square can be used to set the index plate to the mill table.

I've drawn up more elaborate indexing plate and the drawing are available at my store as a PDF digital down load for $4US.

Kits For The Home Shop Machinist/Tinkerer

Kits for the home shop machinist. Hi my name is Doug Gray thanks for stopping by my shop. I'm am the sole proprietor of D. Gray Drafting and Design. I lovingly create all the kits you see here in my shop. Everything from creating the drawing to assembling all the materials and packaging them up...

d-gray-drafting-and-design.myshopify.com

This is one of those questions that I suspect most are too embarrassed to ask but not me.

How do you locate and drill two holes opposite from each other (180 degrees) on round stock. I am attempting to build a solid rear axel for a Tonka truck conversion with a set of bevel gears in the center as a locked differential.

Here is a picture of the stock I'm starting with.

The first iteration of this I milled a flat on the first side and flipped it over and milled the opposite side flat giving me the 180 degree opposite flat. Then I drilled the holes, but for this one I was going to leave it round.

This is likely one of those things that tomorrow morning it will seem simple, but right now, not so much. I hope this generates an educational discussion

v block, thru drill, rotate 90, pin both ends, rest on v block, drill again.This is one of those questions that I suspect most are too embarrassed to ask but not me.

How do you locate and drill two holes opposite from each other (180 degrees) on round stock. I am attempting to build a solid rear axel for a Tonka truck conversion with a set of bevel gears in the center as a locked differential.

Here is a picture of the stock I'm starting with.

The first iteration of this I milled a flat on the first side and flipped it over and milled the opposite side flat giving me the 180 degree opposite flat. Then I drilled the holes, but for this one I was going to leave it round.

This is likely one of those things that tomorrow morning it will seem simple, but right now, not so much. I hope this generates an educational discussion. Thanks for the support!

Jim

Look up 'Rose-Index'. Saw them on a Tubal Cain video. Pricey but they are great. Other-wise, I measure the circumference with a flexible measuring tape and using the metric scale; 'cause it's more versatile in this instance. Mark your starting point, measure circumference, divide by two and mark your second point. You'll be within a millimeter.

- Joined

- Apr 8, 2013

- Messages

- 2,021

If you need to pin one particular part to another particular part and don't need parts interchangeability, just stick the shaft into the bore and drill thru the whole mess. You won't get a better fit. I have two sons and I used this trick on countless go carts, dune buggies, and go carts thru the years.

If drilling holes across the round stock drill from one side and not from the end easy one shot.

Strike a ring or line at distance from an end.

Place in a vise held by faces and on parallels to insure square and above bottom.

Drill with your mill or if using drill press more care.

Place a dial indicator in the chuck as if it was a drill.

Have the point on your line and shift until dial indicator indicates true center.

Place smallest center drill you have in chuck at a high speed and gently touch the work to put a dimple in the work.

Reduce speed to normal for size and drill a starter point.

Change to final size just top side.

Since you are on exact center the opposite side should be lowest point.

You can either use same drill as top and increase speed as before and tap the bottom or replace drill with a center punch held in chuck that runs true and tap it with the feed just to make a center mark then drill it out.

Or with the center finder on your square you can mark both sides then with a square scribe the lines but much easier to just drill from one side.

If from ends pre drill through then bore

Sent from my SM-G781V using Tapatalk

Strike a ring or line at distance from an end.

Place in a vise held by faces and on parallels to insure square and above bottom.

Drill with your mill or if using drill press more care.

Place a dial indicator in the chuck as if it was a drill.

Have the point on your line and shift until dial indicator indicates true center.

Place smallest center drill you have in chuck at a high speed and gently touch the work to put a dimple in the work.

Reduce speed to normal for size and drill a starter point.

Change to final size just top side.

Since you are on exact center the opposite side should be lowest point.

You can either use same drill as top and increase speed as before and tap the bottom or replace drill with a center punch held in chuck that runs true and tap it with the feed just to make a center mark then drill it out.

Or with the center finder on your square you can mark both sides then with a square scribe the lines but much easier to just drill from one side.

If from ends pre drill through then bore

Sent from my SM-G781V using Tapatalk