- Joined

- Dec 30, 2014

- Messages

- 259

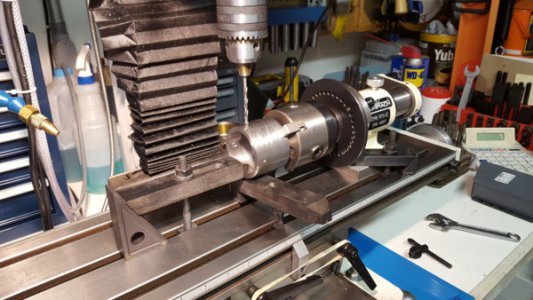

Here is my solution, I think this was suggested above....

I bored out a tube to hold my part, then milled flats on opposite sides. Then drilled a hole in the center of each flat.

Smaller part installed in the holder while I center drilled the holder.

Gear and axel installed. I think my original hole caused the first one to be off just a bit since the gear is almost exactly the size of the ID , I had to mill a tiny bit of clearance.

Jim

I bored out a tube to hold my part, then milled flats on opposite sides. Then drilled a hole in the center of each flat.

Smaller part installed in the holder while I center drilled the holder.

Gear and axel installed. I think my original hole caused the first one to be off just a bit since the gear is almost exactly the size of the ID , I had to mill a tiny bit of clearance.

Jim