yes.... sorry for the oversight.Assuming the OP meant 12 inches and not 12 feet?

Clint

yes.... sorry for the oversight.Assuming the OP meant 12 inches and not 12 feet?

Thank you. I was fearful of that. It will give me a goal and reason for a larger lathe once I learn the basics on this lathe.Your lathe is too small for what you propose to do.

It is surprisingly easy to make a tap that will cut threads into aluminium. Only slightly harder to make a die with matching external threads. Deep hole drilling on the mill is possible by swinging head and fixturing work off back of table.

You are enlarging an existing hole you could even make up a pull through drill with a bushing to ride the existing bore and removable shanks of differing lengths. I'd modify a purchased drill for that.

It's more about the length of the boring bar. If you want to do the boring in one pass, you need a bore that is the depth of the hole (12"), and since that bore is going to be 100% outside of the hole when you start, the lathe has to have enough room for the 12" part, the 12" bore, and the tailstock to hold the boring bar.I three times the depth you wish to drill a good formula to use?

As Jim D mentions, optimally I would need a 36" bed lathe when wanting to drill 12" part. That's the kind of fats I would not think of. I three times the depth you wish to drill a good formula to use?

I tried drawing it up and it sucked, I am no artist, even with computer assistance. Pick up a drill and look head on at the pointy end. Imagine a hole bored through the long axis that extends all the way through the length of the drill. Run a piece of round stock through that bore. Now put a pin through both to hold them together with the length of the stock extending out of the point. This is now your shank. Run the shank through the stock you want to drill and put it in the tail stock. Instead of pushing the tail stock toward the work you will pull it through the work by backing it away from the headstock.Can you expand on how this process would work?

Thanks,

Clint

You don't really need 3X the depth to drill a part. But you do need a minimum of 2X (part + drill bit) the depth + the chuck stick out from the spindle + enough room to keep the tailstock on the ways. A 36 inch lathe has a maximum center to center length of 36 inches, but with a chuck on it you have reduced the working length by the thickness of the chuck. By the time you add in a drill chuck or some other holding method you have reduced the working length again by some amount.

The maximum depth that I can drill in my 13x48 is 22 inches, unless I can put the part through the headstock bore. I designed this part to fit in the lathe, I really wanted it 24 inches long but there was no way I could get it in there.

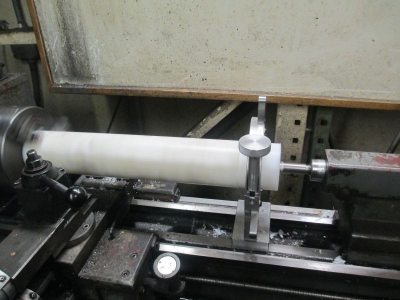

Here is a 22 inch part set up, you can see the tailstock hanging off of the ways a bit, was just able to clamp it. Drill bit tip to tailstock nose is 22.5 inches. Allowed me to just break through with the full diameter of the bit.

View attachment 306824

View attachment 306825

Jim, this is perfect. As they say ; a picture is worth a thousand words. Is that a three point steady rest?You don't really need 3X the depth to drill a part. But you do need a minimum of 2X (part + drill bit) the depth + the chuck stick out from the spindle + enough room to keep the tailstock on the ways. A 36 inch lathe has a maximum center to center length of 36 inches, but with a chuck on it you have reduced the working length by the thickness of the chuck. By the time you add in a drill chuck or some other holding method you have reduced the working length again by some amount.

The maximum depth that I can drill in my 13x48 is 22 inches, unless I can put the part through the headstock bore. I designed this part to fit in the lathe, I really wanted it 24 inches long but there was no way I could get it in there.

Here is a 22 inch part set up, you can see the tailstock hanging off of the ways a bit, was just able to clamp it. Drill bit tip to tailstock nose is 22.5 inches. Allowed me to just break through with the full diameter of the bit.

View attachment 306824

View attachment 306825

MontanaLon ,I tried drawing it up and it sucked, I am no artist, even with computer assistance. Pick up a drill and look head on at the pointy end. Imagine a hole bored through the long axis that extends all the way through the length of the drill. Run a piece of round stock through that bore. Now put a pin through both to hold them together with the length of the stock extending out of the point. This is now your shank. Run the shank through the stock you want to drill and put it in the tail stock. Instead of pushing the tail stock toward the work you will pull it through the work by backing it away from the headstock.

I know it sounds complex but this is how they used to drill rifle barrels before metal lathes were common in the days of muzzle loaders. They did this with a bench vise and a 2 foot long T-handle for the drill. Most of the barrels back then started out as flat stock which was then forged into a tube and forge welded around a mandrel. Naturally the bore would be rough after that but it is way easier to pull a drill straight than it is to push it and have it go straight.

It still happens that way today with button rifled barrels. They pull the button through as pushing it would be a chore.