- Joined

- Nov 6, 2021

- Messages

- 60

I'm sure this question been asked before, but I couldn't find it using search. So, I'm a beginner at metal milling and I was working on a project today and about midway through the project it seemed as if the cutting was struggling a bit more than it was in the beginning. It wasn't extreme, but did seem that it wasn't cutting as easily as earlier. This made me wonder how I know when it's time to get my end mill sharpened.

The specifics are:

Milling a recess in a block of 6061 aluminum, End Mill is a 3/4" 4 flute HSS end mill that I bought from LMS (my Mill is a mini 3990). They're coated with some kind of gold coating. Spindle RPM a little over 1000.

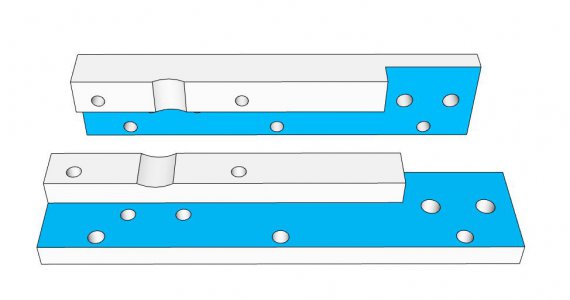

I have added power feed to the X axis and it's probably around 9-10 IPM. It doesn't have speed control. Most of the cuts were using power feed. I initially started cutting 0.020" deep per pass but that seemed too slow so I increased the depth to about 0.040" per pass. I used Tap Magic Aluminum as brush on lubricant. Most passes were about 6.5" long, 0.312" wide per pass. Overall I cut about 0.375" deep and about an inch wide. All passes were conventional cut, with a climb cut retrace back to the start.

Not sure what more you need...

The specifics are:

Milling a recess in a block of 6061 aluminum, End Mill is a 3/4" 4 flute HSS end mill that I bought from LMS (my Mill is a mini 3990). They're coated with some kind of gold coating. Spindle RPM a little over 1000.

I have added power feed to the X axis and it's probably around 9-10 IPM. It doesn't have speed control. Most of the cuts were using power feed. I initially started cutting 0.020" deep per pass but that seemed too slow so I increased the depth to about 0.040" per pass. I used Tap Magic Aluminum as brush on lubricant. Most passes were about 6.5" long, 0.312" wide per pass. Overall I cut about 0.375" deep and about an inch wide. All passes were conventional cut, with a climb cut retrace back to the start.

Not sure what more you need...