- Joined

- Dec 18, 2019

- Messages

- 7,333

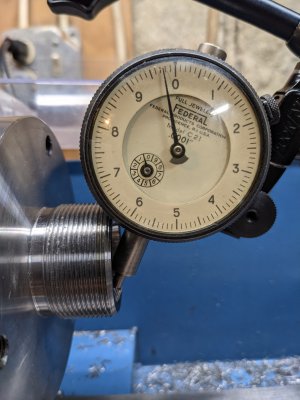

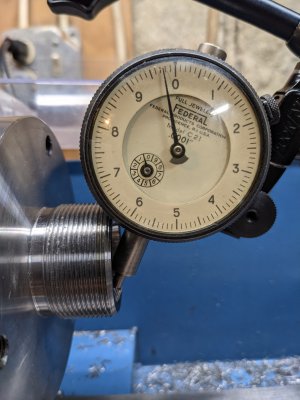

Ok, did it again. The dial indicator had a little stiction, and would drag a little at the start of rotation. I added a drop of oil to the surface and remeasured. The oil helps. So it's not 0.00001". It's just under 0.0001". Wish the Noga was slightly bigger (in this case) but I was able to take the measurement.

Even though it looks like it, the body of the indicator is not touching the chuck. As you can see, (third picture) the indicator is pushed in 0.010". (1|0 line) When it's at full extension, the small indicator is on the 0|9 line. When I rotate the chuck 360 degrees, the big needle only varies between two minor divisions, which is under 0.0001".

I have a DTI, but it only has 0.0005" marks. It sure would be easier to use, however. I might have cosine error with the dial indicator, as I'm not normal to the surface. If I extended the plunger on the dial indicator, maybe I could get closer to normal.

But this second measurement seems to tell me, stuff isn't too bad. Not sure about fixturing repeatability, but at least this measurement is ok. Comments? Did I do this right? What would you do different? (Besides not buying a mini lathe...)

Even though it looks like it, the body of the indicator is not touching the chuck. As you can see, (third picture) the indicator is pushed in 0.010". (1|0 line) When it's at full extension, the small indicator is on the 0|9 line. When I rotate the chuck 360 degrees, the big needle only varies between two minor divisions, which is under 0.0001".

I have a DTI, but it only has 0.0005" marks. It sure would be easier to use, however. I might have cosine error with the dial indicator, as I'm not normal to the surface. If I extended the plunger on the dial indicator, maybe I could get closer to normal.

But this second measurement seems to tell me, stuff isn't too bad. Not sure about fixturing repeatability, but at least this measurement is ok. Comments? Did I do this right? What would you do different? (Besides not buying a mini lathe...)