- Joined

- Jan 16, 2017

- Messages

- 216

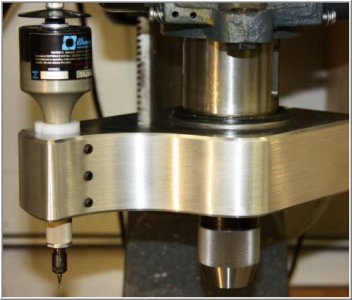

carbide end mill straight down

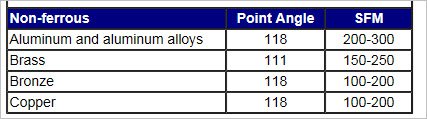

Was this going to be a through hole? If so, you can try drilling from the back side. When you hit the broken drill, you may just pop it loose. if not, take a piece of piano wire slightly smaller than your drill size and gently try to tap it out. If the exit hole size isn't critical, you can use a larger drill which will improve your chances of properly hitting the broken drill.

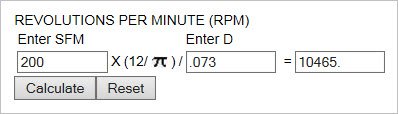

It is difficult to hit dead on. But we are talking about how to salvage an otherwise ruined part. I have done this on a number of occasions with success. I will drill a smaller diameter hole from the backside to allow me to clean up the final hole like Eddy said.How would you hit a .073" drill from the other side dead on? Even with a DRO this would be a hard trick.

That's a good idea. I don't know how strong the part needs to be, but a pressed in aluminum plug may just be the answer.Could you drill a larger hole, press in an aluminum rod then mill flush??? Don't know how pretty it needs to be or if this would even work. Just a thought.

Could you drill a larger hole, press in an aluminum rod then mill flush??? Don't know how pretty it needs to be or if this would even work. Just a thought.