- Joined

- Dec 10, 2023

- Messages

- 85

Hello, i have not done any lathe work. So bear that in mind.

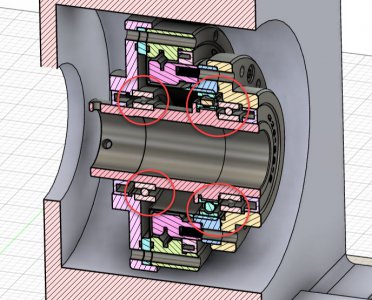

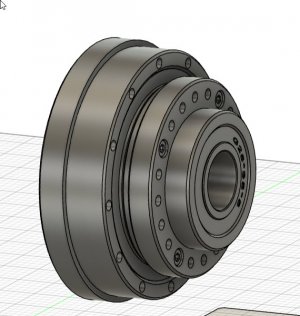

I am designing my own 4th axis for my Tormach 770.

I have lots of experience with Stepper motors and harmonic gears that i will be using to make the 4th axis as i build astronomy mounts that use them.

My questions revolve around putting a Lathe Chuck and Collet chuck on the end of the harmonic gear box.

I do not know anything about spindle noses that 3/4/6 jaw chucks and collet chucks attach too.

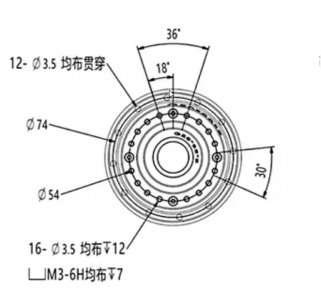

I attached the bolt pattern that is on the harmonic gear box to this post. You can see the bolt pattern has a diameter of 54mm or 2.126 inches.

I would be using a 4 inch chuck most likely.

If anyone has suggestions on the best nose to buy/make/use for this application please let me know.

Thanks!

Chad

I am designing my own 4th axis for my Tormach 770.

I have lots of experience with Stepper motors and harmonic gears that i will be using to make the 4th axis as i build astronomy mounts that use them.

My questions revolve around putting a Lathe Chuck and Collet chuck on the end of the harmonic gear box.

I do not know anything about spindle noses that 3/4/6 jaw chucks and collet chucks attach too.

I attached the bolt pattern that is on the harmonic gear box to this post. You can see the bolt pattern has a diameter of 54mm or 2.126 inches.

I would be using a 4 inch chuck most likely.

If anyone has suggestions on the best nose to buy/make/use for this application please let me know.

Thanks!

Chad