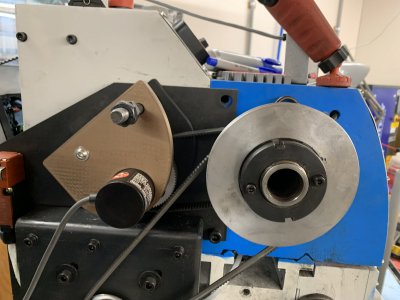

After a LONG time (and a couple errors) I Finally had time to tear apart the lathe (1030V) and install the bench tested ELS (Clough 42)

It is working (not tested thread pitch yet of course) and all seems to work well.

The only issue I have is keeping the darn connector in the servo. The power has screws, but the others do not. It is a bit cramped in there to plug them in anyway (under the ways), although I did not have any issues getting the servo in there on the mount I 3D printed.

I suppose a dab of silicone? I am open to ideas.

I hooked up the programming cable too, as long as it is not hooked up, leaving it connected seems ok- then I can change something if needed. Am I wrong?

Thanks for all (especially Tammy) for the help getting it all together. I will have the final 3Dprint files if anyone wants them (or I could print them). But best to wait until I run it awhile and make sure no mistakes. I already goofed up on the encoder mount. It was fine on the slow belt speed, but would hit on high. I have never used the high speed (and maybe never will) but silly not to fix it so I can. It was an easy change in Fusion 360 and just send to printer.

Mark