Today i am cleaning out my garage. To get into the process of finishing my garage for a moisture tight zone. I am hoping by next weekend i will have atleast the section in the garage (roughly 10-15ft from the back wall forward) painted so i can finally after 2 years set my machines to their resting place.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Group Project: Dividing Head - The Build

- Thread starter Flyinfool

- Start date

- Joined

- Mar 25, 2013

- Messages

- 5,131

Y'all may notice that some of my counterbores are off center by 5-10 thou. I am not at all sure how that happened? I need to re-check my tram and my zero position.

This will not at all affect function and will not be easily visible. Nevertheless, I don't like it.

Robert

This will not at all affect function and will not be easily visible. Nevertheless, I don't like it.

Robert

- Joined

- Aug 3, 2017

- Messages

- 2,437

Used as much time as I had today to do some learning

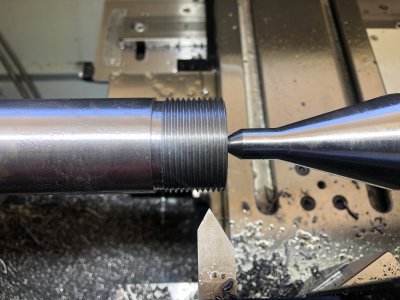

Since I'm blocked on the gears for a while, I decided to start on the shaft. The important dimension is a 1" long 1-4 Acme thread, which you saw I ground a tool for.

First, I cut the 1" and cut in my thread relief (to .700 as on the drawing).

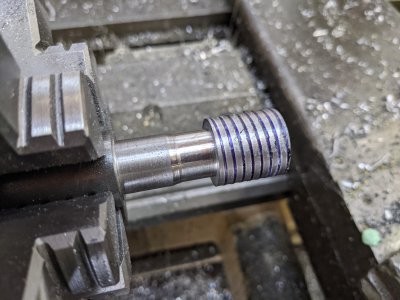

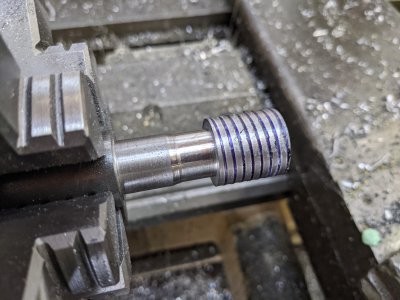

Next, I spent a while bluing and lining up my threading tool.

Then, I set to do my scratch pass! Only, it was a bit more than a scratch. AND it was 8TPI. I forgot to set one of my gear levers :/

Unfortunately it ended up being too deep, and cleaning it up left this part too small by about 18 thou. However, I went ahead to try to cut my first Acme thread as practice.

Overall, it turned out alright! I tried two mechanisms for finishing the ends, the left is to just file off the partial thread, the right is trying a chamfer tool. Overall, the filing ended up nicest.

Additionally, the threads are a little too tight on the hobbing tool. I cut to the exact ID of the hobbing tool, but I suspect I need to dress the tip of my cutting tool to be a touch wider.

Anyway, good learnings and only ruined 1 part! (Or perhaps none of I can just turn this off and use it as the small side of the shaft).

Since I'm blocked on the gears for a while, I decided to start on the shaft. The important dimension is a 1" long 1-4 Acme thread, which you saw I ground a tool for.

First, I cut the 1" and cut in my thread relief (to .700 as on the drawing).

Next, I spent a while bluing and lining up my threading tool.

Then, I set to do my scratch pass! Only, it was a bit more than a scratch. AND it was 8TPI. I forgot to set one of my gear levers :/

Unfortunately it ended up being too deep, and cleaning it up left this part too small by about 18 thou. However, I went ahead to try to cut my first Acme thread as practice.

Overall, it turned out alright! I tried two mechanisms for finishing the ends, the left is to just file off the partial thread, the right is trying a chamfer tool. Overall, the filing ended up nicest.

Additionally, the threads are a little too tight on the hobbing tool. I cut to the exact ID of the hobbing tool, but I suspect I need to dress the tip of my cutting tool to be a touch wider.

Anyway, good learnings and only ruined 1 part! (Or perhaps none of I can just turn this off and use it as the small side of the shaft).

Attachments

- Joined

- Aug 3, 2017

- Messages

- 2,437

I did think about tail support and even cut a center, but I didn't end up having any noticable deflection. I cut a few spring passes, and they all seemed about even.Nice work Erich. Do you think support from a center would help at all?

R

In exchange I got to start my tool further away in case I missed my half but engagement and therefore could run the lathe a bit faster (as well as minimize stickout!) So I think the exchange was worth it.

- Joined

- Sep 8, 2019

- Messages

- 4,392

- Joined

- Aug 13, 2020

- Messages

- 1,342

@ErichKeane , did you consider rough cutting the material out with an indexable tool, to save wear on your ground one?

I didn't make any progress. . . . or did I !?

It turned out that I burned up the motor, and not the controller. The problem with most of these free treadmills that pop up on Craigslist, tends to be the controllers. The MOSFETs (big transistor thingy) are life limited, so it is pretty much planned obsolescense. Getting a motor replacement is much easier/cheaper than replacing the electronics.

I had a 1.75Hp sitting on the shelf, but I decided to tear into the unit that I have yet to tear apart. It's a name brand model. Bowflex. And, it gifted me with a beautiful 3Hp unit. I had to spend the day yesterday turning a pully for it. I had a 1" thick, 3" dia puck left from my uncle's shop press project. So I pressure turned for the first time. Here are the new and old,

![KIMG0794[1].JPG KIMG0794[1].JPG](https://www.hobby-machinist.com/data/attachments/326/326289-43c7c88ada3c644488a1496fe3e36d49.jpg)

I had to modify the mount, but once I got the new motor installed, I was happy that I could barely make out that the motor was even running. I was unhappy that it was running backwards. I opened the control panel back up, swapped the leads, and was in business. Finished the facing I started Friday night in just a few minutes. It really is so much smoother. I think I have a very good chance of burning up some end mills with this new power. And for some reason, the finish is my best yet. I think that is because the machine is not getting slowed down when it enters the cut.

![KIMG0795[1].JPG KIMG0795[1].JPG](https://www.hobby-machinist.com/data/attachments/326/326291-4d139601f77829a389c8d08b3f766e0e.jpg)

I didn't make any progress. . . . or did I !?

It turned out that I burned up the motor, and not the controller. The problem with most of these free treadmills that pop up on Craigslist, tends to be the controllers. The MOSFETs (big transistor thingy) are life limited, so it is pretty much planned obsolescense. Getting a motor replacement is much easier/cheaper than replacing the electronics.

I had a 1.75Hp sitting on the shelf, but I decided to tear into the unit that I have yet to tear apart. It's a name brand model. Bowflex. And, it gifted me with a beautiful 3Hp unit. I had to spend the day yesterday turning a pully for it. I had a 1" thick, 3" dia puck left from my uncle's shop press project. So I pressure turned for the first time. Here are the new and old,

![KIMG0794[1].JPG KIMG0794[1].JPG](https://www.hobby-machinist.com/data/attachments/326/326289-43c7c88ada3c644488a1496fe3e36d49.jpg)

I had to modify the mount, but once I got the new motor installed, I was happy that I could barely make out that the motor was even running. I was unhappy that it was running backwards. I opened the control panel back up, swapped the leads, and was in business. Finished the facing I started Friday night in just a few minutes. It really is so much smoother. I think I have a very good chance of burning up some end mills with this new power. And for some reason, the finish is my best yet. I think that is because the machine is not getting slowed down when it enters the cut.

![KIMG0795[1].JPG KIMG0795[1].JPG](https://www.hobby-machinist.com/data/attachments/326/326291-4d139601f77829a389c8d08b3f766e0e.jpg)

- Joined

- Aug 3, 2017

- Messages

- 2,437

I didn't consider that, no.... though I've never had luck re-indexing threads before, so I'm a touch scared to@ErichKeane , did you consider rough cutting the material out with an indexable tool, to save wear on your ground one?

Cleaning up the grind is pretty easy though I think, so Im not particularly afraid of wearing it out in this case.