- Joined

- Aug 22, 2012

- Messages

- 4,260

When you do not have either a lathe or a mill its amazing what you can do with a drill press.

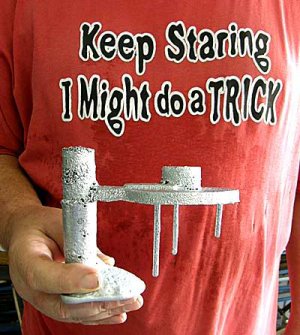

I needed some custom pulleys for the cable steering for my lowrider bicycle so I made them.

Cast two pulley blanks

roughly cleaned and drilled for a bolt, the lock screw prevents the pulley slipping when turning.

When all the turning was done I cut the boss from the disk using a hole saw

Set up in the drill press with an epoxied chuck and faced it off with an old file ground to an edge. I clamped a block to the table to brace the turning tools against, just like wood turning.

Then turned the dia to size with the same tool.

For the pulley groove I ground a rounded tool from an old rat tail file.

These were made nearly 7 years ago and are still in use on the bicycle today.

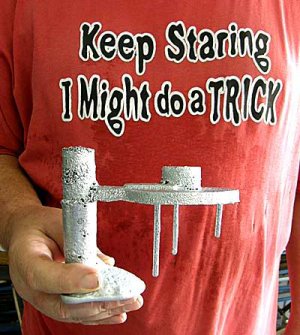

I needed some custom pulleys for the cable steering for my lowrider bicycle so I made them.

Cast two pulley blanks

roughly cleaned and drilled for a bolt, the lock screw prevents the pulley slipping when turning.

When all the turning was done I cut the boss from the disk using a hole saw

Set up in the drill press with an epoxied chuck and faced it off with an old file ground to an edge. I clamped a block to the table to brace the turning tools against, just like wood turning.

Then turned the dia to size with the same tool.

For the pulley groove I ground a rounded tool from an old rat tail file.

These were made nearly 7 years ago and are still in use on the bicycle today.