- Joined

- Feb 23, 2016

- Messages

- 479

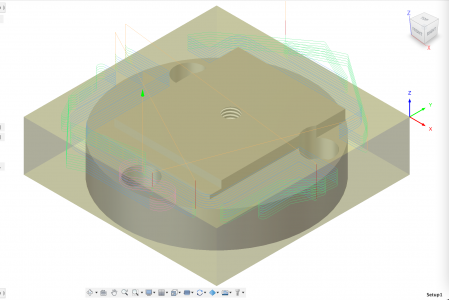

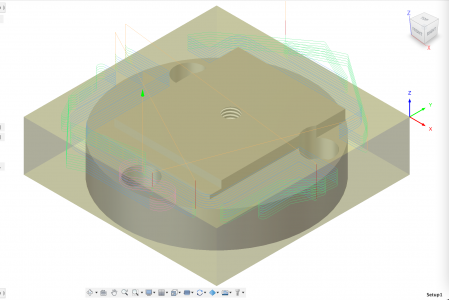

I struggle with completing parts, and don't know how to release them from the stock. Consider this part:

It is a simple circular adapter with four holes and a protrusion with a shoulder. Overall 0.5" thick, and working it out of 0.64" thick alu plate. I was able to to the spot drilling, through drilling, and the rest of contours, but then I am left with a piece still attached at the bottom in the stock. What are the best practices to complete the job?

This time I took a crude approach and cut the contour out with a bandsaw then flipped into the vise using the stickout and am going at it with a fly cutter, little by little, but would like to program this (the first face with all the steps was CNC'd). Any advice is greatly appreciated.

It is a simple circular adapter with four holes and a protrusion with a shoulder. Overall 0.5" thick, and working it out of 0.64" thick alu plate. I was able to to the spot drilling, through drilling, and the rest of contours, but then I am left with a piece still attached at the bottom in the stock. What are the best practices to complete the job?

This time I took a crude approach and cut the contour out with a bandsaw then flipped into the vise using the stickout and am going at it with a fly cutter, little by little, but would like to program this (the first face with all the steps was CNC'd). Any advice is greatly appreciated.