Johnny has found that book and went through it. I don't know how thoroughly, but we are looking at belt options next. Thanks everybody for the help.

Southbend's HTRAlL was a good call from Brino. Almost everything is in there somewhere.

As for a belt, you have a few options. If the machine will not be relocated the automotive timing belt is the preferred option (imho). That belt requires removal of the headstock spindle and countershaft.

I use the clip laced leather belts, because they are the easiest to repair /replace.

Early leather flat belts were laced, literally with soft wire or cat gut.

There are also guys that glue their belts, leather or rubber or even automotive seat belt.

In general i find with SBL: when in doubt, stick to the configuration it had when it left the factory.

lk

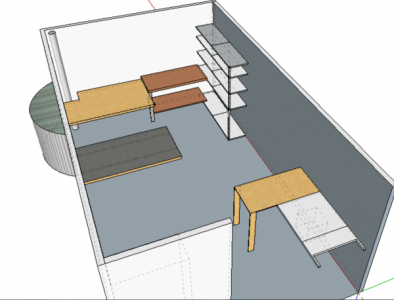

This edit might help:

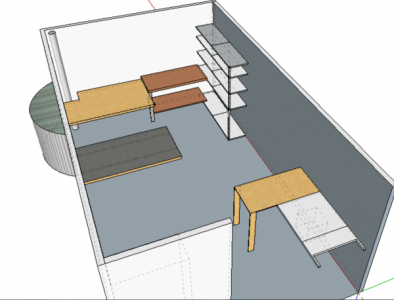

This is from WSWells:

Up until 1934 SB lathes we coated with japanning.

Series "O" machines had the single wall apron.

Series "O" all have a star knob that is loosened shifted and tightened to select cross, neutral or long feeds.

Series "N" aprons have a knob that you push in and pull out for this function.

The double wall apron series "N" may not have been made after the late thirties (1937) due to market forces.

The R series lathes came out in the early thirties (1934). An R series lathe can always be identified because it will have the double wall apron with the more modern feed shift handle rather than star knob shifter.

If your workshop lathe is a 34 or 35 it's a catalog 405. It can be identified by the 1 3/8-10 spindle thread and the fact that it has no reveres shifter and the lead screw is left hand thread. If it does not have these three things then its not a 405. If it has the 1 1/2-8 spindle thread and has two bolts to hold each spindle bearing cap on its a catalog 520 toolmakers lathe. If it has just one bolt on each head stock bearing cap and has the 1 1/2-8 spindle and has a reverse shifter with right hand thread lead screw its a catalog 415. All three of these lathes will have the spindle oilier on top of the head stock bearing caps.

>>>>>