- Joined

- Mar 21, 2018

- Messages

- 1,716

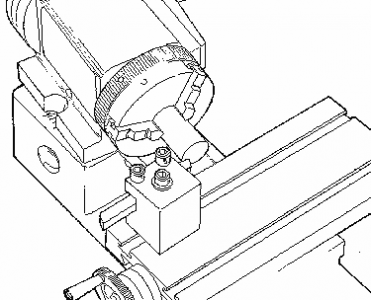

In the picture in post #19, the cutoff blade doesn't look vertical. For cutting square shoulder grooves, you probably should make a form tool for them, instead of using a cutoff tool. Your parting blade is 0.040" wide. That makes it extremely difficult to use - if it isn't set up perfectly, your chances of breaking the blade are very high. When parting, lubrication is required - continuous flood, if possible. If not, then a brush loaded with the fluid continually painting the cut is needed. The oil is not really for the cut, but is instead for lubricating the sides of the tool and the part, since they have zero clearance.

As for cutting a taper, I hope that you meant offsetting the tailstock instead of "turning the headstock". I don't know of a lathe where you can "turn the headstock". For a better finish, a radius on the end of your tool will greatly improve the looks. Also, hone it to a very sharp condition.

As for cutting a taper, I hope that you meant offsetting the tailstock instead of "turning the headstock". I don't know of a lathe where you can "turn the headstock". For a better finish, a radius on the end of your tool will greatly improve the looks. Also, hone it to a very sharp condition.