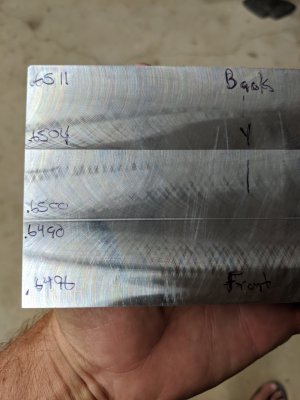

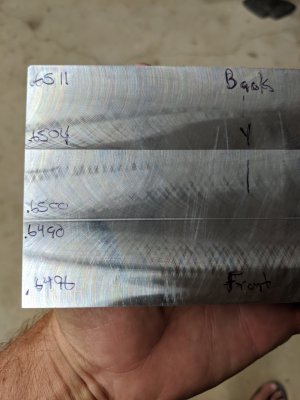

Leaving a ridge parallel to the direction of cut when facing can only be due to one thing. The spindle axis is not perpendicular to the ways that are perpendicular to the direction of cut. It is typically assumed that tramming the spindle to the table is equivalent to tramming to the ways and that is not necessarily true.

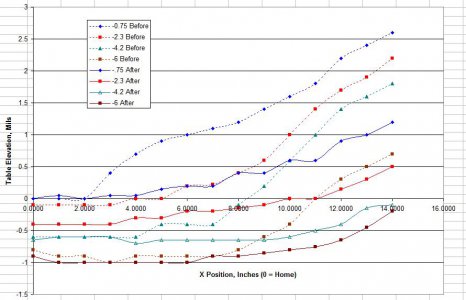

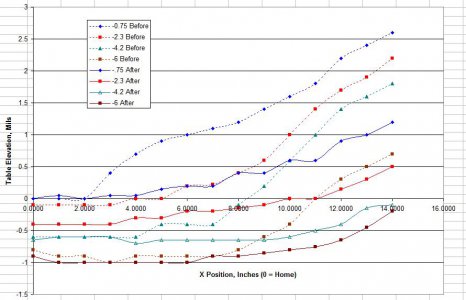

A sweep of the table in x and y directions with a DTI can reveal a non parallel condition although one has to be aware of extenuating conditions such as loose gibs, e.g. When the table is moved to an extreme condition, the center of gravity can be over an unsupported region and the table can tilt. Here is a graph showing this tilt and the improvement when the gibs are adjusted.

The method that I use to tram the spindle is to clamp a piece of plate to the the table and mill a circular path equal in diameter to the path of tramming tool.using a small diameter end mill. The path by default will be parallel to the x and y ways. For a manual mill, four elevated bosses at the + and - extents in x any y can be created. These surfaces will be the tramming points.

In the case of your mill, a non trammed condition in the y direction can be caused by several factors. The spindle may not be parallel to the z axis ways. The z axis gib can be too loose, causing the head to droop slightly. The quill may have excessive play causing sag. The mill column may not be perpendicular to the y axis ways. Your axes can be locked down which will eliminate any tilt due to loose gibs. You can also lock the quill which will effectively eliminate play.

A simple check for tram is to face in both directions. A properly trammed spindle will have a similar cut pattern . If you have cross hatching in one direction but not the other, you have an out of tram condition. Small mills will experience deflection due to cutting force which will raise the trailing side of the facing tool, causing the arcs to be be facing the same way. If the out of tram condition equals or exceeds the cutting force deflection, the back side of the tool contacts the surface resulting in a cross hatch pattern. Depending on the depth of cut and rigidity of the machine, a very light cut or second pass on a well trammed machine can still yield a cross hatch pattern.