I made some progress mounting the scale for the X axis on my lathe. I spent a bunch of time trying to figure out the best place to mount the scales, and after some debating with myself i decided to place it above the cross slide gib adjustment screws and with the reader towards the back of the saddle. With the cover on i shorten by tailstock travel by less than .5" so that's not terrible. Drilled, tapped, leveled and the scale mounted to the bracket. Here's what it looks like:

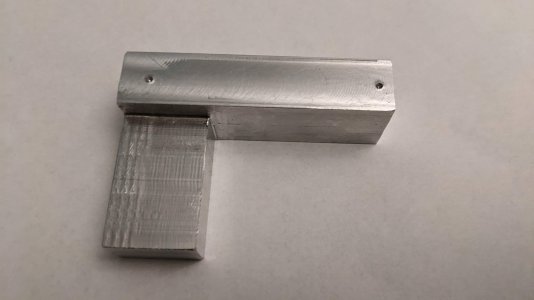

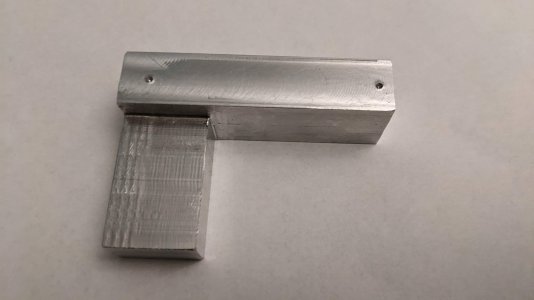

I wasn't sure if it was a good idea to mount the read head with only one bolt and while it might have been OK i decided to make another part. Well truth be told i made a new part twice! In the layout i flipped the part around enough times that i ended up laying it out so that the leg was on the wrong side, Darn it!

Re-made the part with the leg on the correct side.

Got as far as center punching the holes for the read head screws but no drilling or tapping.

The pieces are aluminum and look way rougher than they feel. I'm an amateur at best so i'm pretty thrilled that i've hit my tolerances so far.

Don't know if i really had to remake this piece as it seemed affixed quite firmly but i didn't want to have to pull the lathe away from the wall, take off the splash guard and potentially replace the reader if it gets broken in the future. I did find out that after all of the comparisons on AliExpress i did end up with 5 Micron scales for both the X and Z. I had thought that the X axis was 1 Micron as it was a slim line model built for the cross slides but i attempted to purchase both scales from the same seller and clearly didn't pay enough attention when ordering.

Making progress, slowly but surely.

I wasn't sure if it was a good idea to mount the read head with only one bolt and while it might have been OK i decided to make another part. Well truth be told i made a new part twice! In the layout i flipped the part around enough times that i ended up laying it out so that the leg was on the wrong side, Darn it!

Re-made the part with the leg on the correct side.

Got as far as center punching the holes for the read head screws but no drilling or tapping.

The pieces are aluminum and look way rougher than they feel. I'm an amateur at best so i'm pretty thrilled that i've hit my tolerances so far.

Don't know if i really had to remake this piece as it seemed affixed quite firmly but i didn't want to have to pull the lathe away from the wall, take off the splash guard and potentially replace the reader if it gets broken in the future. I did find out that after all of the comparisons on AliExpress i did end up with 5 Micron scales for both the X and Z. I had thought that the X axis was 1 Micron as it was a slim line model built for the cross slides but i attempted to purchase both scales from the same seller and clearly didn't pay enough attention when ordering.

Making progress, slowly but surely.