Thanks, that sound like a decent size to open the material up to initially. So the real dumb questions will be coming now. Opening the 0.875" to a finished 25.00mm, boring the 6061 aluminum, about how much material should I limit to removing with each pass?

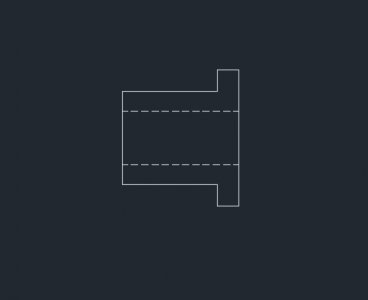

That was my thought, to basically make the shape of the spacer, and face both ends to the proper length first, then check the run out of the part in the chuck before boring. This also will be a stepped, or a flange on one end of the spacer. It'll look like this attached. I have to acquire a few more parts before I can determine all of the finished dimensions.