Dear fellow hobby machinists,

I am very excited that I just received a beautiful new Deckel FP1. The previous owner has owned and cared for it for about 14 years but with numerous other larger machines including DMG Mori 5 axis and numerous Haas machines each larger than a typical studio apartment, he wanted to make room. This machine is exceptionally well maintained. I knew from talking to the previous owner and his friend who works in his shop that they both cared a lot for this machine. It comes with all the accessories I would want to use. And a few that I don't have an immediate use for including the famous helical milling attachment. They all appear lightly used if used at all. I also have tons of those special Deckel collets and various adapters, boring heads etc. I paid next to nothing for the whole thing so it was literally the machine deal of a lifetime.

It is an FP1 made for the US market so all lead screws and markings are imperial. Not that it matters to me as I will use a DRO and do both imperial and metric parts.

The previous owner and his friend delivered it, leveled it and taught me what sort of precision is possible with a machine like this. My other mill is a nice Taiwanese benchtop (PM728VT) and this is an upgrade. But I was not prepared for HOW precise this machine is. I used to be happy with tramming to about 1/2 thou over 12" on X and about 1-2 thou on Y. It is near impossible to tram the Y on that machine anyway. And it didn't usually hold tram after one heavy cut.

The Deckel was leveled and trammed to less than 1.5 in 10 thou (!) on both axes with far less effort. Not bad for a machine from the 60s. I expect it to hold tram as everything is so rigid on this.

Considering how most people usually end up with an FP1 - buying from a dealer sight unseen or picking it up from storage from the estate of a deceased person, I was exceptionally lucky.

The machine paint is original so it is not perfect after 60+ years. But the ways and other critical surfaces are in nice shape. Everything feels so smooth and tight after my experience with Asian machines.

Other than the mill with fixed plate, everything else is in boxes. I cleaned the machine yesterday and filled it with gear oil.

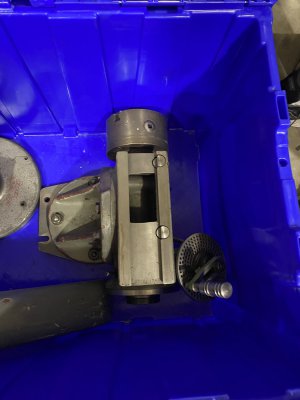

There is lots of stuff now strewn around my garage in boxes and pallets that I will clean up over the next several days.

Will post photos soon.

I am very excited that I just received a beautiful new Deckel FP1. The previous owner has owned and cared for it for about 14 years but with numerous other larger machines including DMG Mori 5 axis and numerous Haas machines each larger than a typical studio apartment, he wanted to make room. This machine is exceptionally well maintained. I knew from talking to the previous owner and his friend who works in his shop that they both cared a lot for this machine. It comes with all the accessories I would want to use. And a few that I don't have an immediate use for including the famous helical milling attachment. They all appear lightly used if used at all. I also have tons of those special Deckel collets and various adapters, boring heads etc. I paid next to nothing for the whole thing so it was literally the machine deal of a lifetime.

It is an FP1 made for the US market so all lead screws and markings are imperial. Not that it matters to me as I will use a DRO and do both imperial and metric parts.

The previous owner and his friend delivered it, leveled it and taught me what sort of precision is possible with a machine like this. My other mill is a nice Taiwanese benchtop (PM728VT) and this is an upgrade. But I was not prepared for HOW precise this machine is. I used to be happy with tramming to about 1/2 thou over 12" on X and about 1-2 thou on Y. It is near impossible to tram the Y on that machine anyway. And it didn't usually hold tram after one heavy cut.

The Deckel was leveled and trammed to less than 1.5 in 10 thou (!) on both axes with far less effort. Not bad for a machine from the 60s. I expect it to hold tram as everything is so rigid on this.

Considering how most people usually end up with an FP1 - buying from a dealer sight unseen or picking it up from storage from the estate of a deceased person, I was exceptionally lucky.

The machine paint is original so it is not perfect after 60+ years. But the ways and other critical surfaces are in nice shape. Everything feels so smooth and tight after my experience with Asian machines.

Other than the mill with fixed plate, everything else is in boxes. I cleaned the machine yesterday and filled it with gear oil.

There is lots of stuff now strewn around my garage in boxes and pallets that I will clean up over the next several days.

Will post photos soon.

Last edited: