Looking at the linked controller manual, it looks like the "plug in horsepower resistor" is not a braking resistor but rather a way of calibrating the controller to motor size. Definitely use the one for your motor's rated HP and voltage. Braking is provided via the "Forward-Brake-Reverse Switch Kit (Part No. 9860)"

It looks like you linked to the KBMD-240d manual. I do have one of those and plan to use it for my lathe, but the version I have for the drill press is the KBMW-240. It does not have a provision for for a FBR switch.Looking at the linked controller manual, it looks like the "plug in horsepower resistor" is not a braking resistor but rather a way of calibrating the controller to motor size. Definitely use the one for your motor's rated HP and voltage. Braking is provided via the "Forward-Brake-Reverse Switch Kit (Part No. 9860)"

I guess I'm just a little sketched out because the amp rating on the motor nameplate falls outside the range the manual suggests should be applicable for a 1/2 hp motor. I think I'll start with a slightly larger fuse and just out a clamp meter on it when I fire it up. That way I can watch the current and see where I'm at.

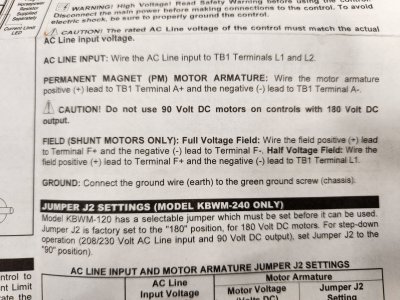

One more question: in the wiring instructions, it tells me that for a "full Voltage field", I wire it one way, and for a "Half voltage field", I wire it another way. Per the plate on the motor, the armature appears to be 180/200 volts and the field 100 volts. Does that mean I wire per the "Half voltage field" instructions?

It looks like in that case, I wire the field negative to the same terminal as one of the AC line wires. That seems weird but again, I'm new to this.

Thanks!