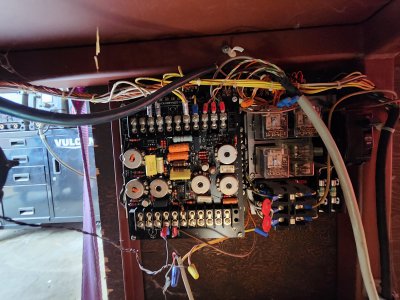

It's hard to grab pictures of the drive since it's hard mounted under the cabinet but here's my attempt. I've been cutting away some of the wood on the cabinet to access things but the control is mounted to the piece of ply along the back of the cabinet so I haven't pulled that one off yet.

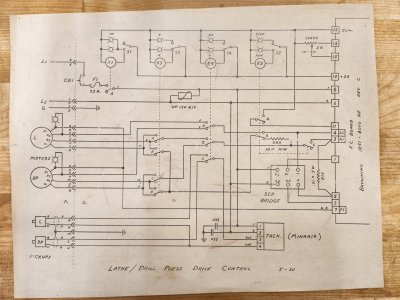

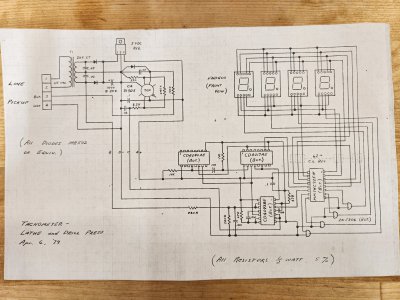

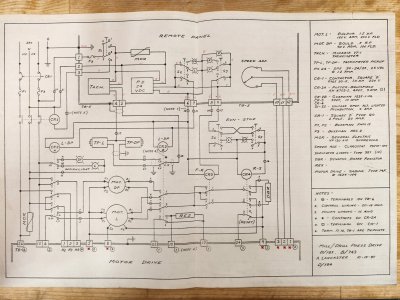

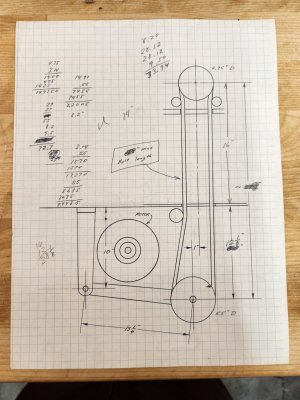

I've attached several pictures of the wiring diagrams drawn by the original owner as well.

I've attached several pictures of the wiring diagrams drawn by the original owner as well.